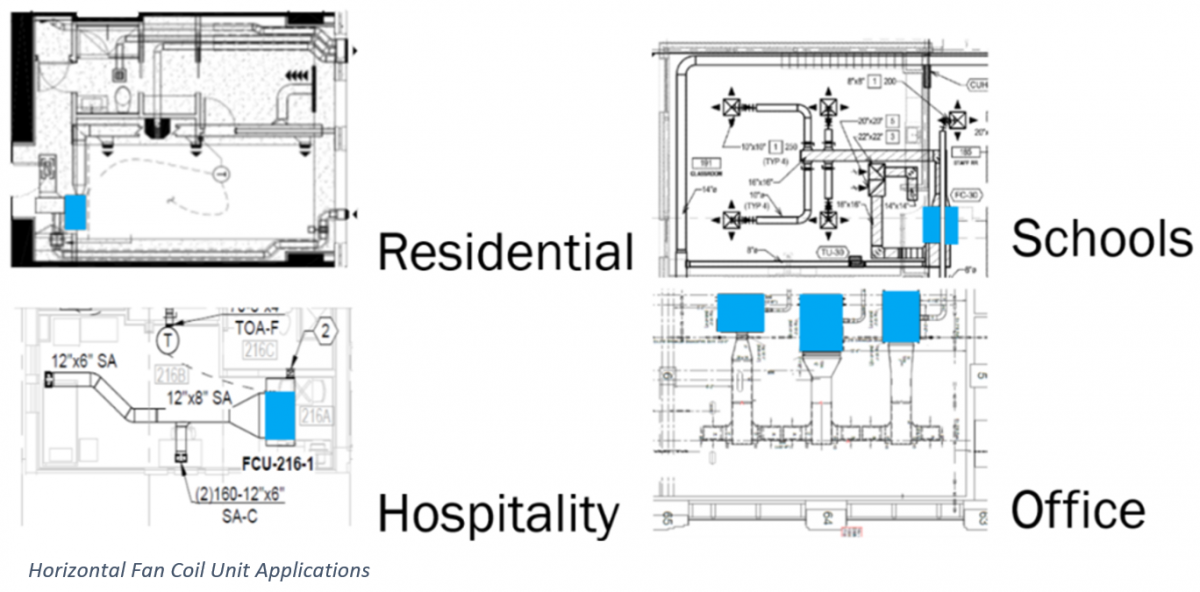

Chilled water fan coils are small air handling units that range from 200-4,000 CFM. Several commercially available product types serve multiple applications. In some instances, choosing which product is best for your application is difficult. There are two main configurations: vertical & horizontal. Horizontal units are typically located above a ceiling while vertical units are installed in a closet or exposed in the room. The selection between vertical and horizontal are made during the building design phase, and there will be little debate over where the project needs a horizontal or vertical. Choosing the right horizontal product for an application requires an understanding of the types available.

Horizontal Fan Coils

While the base building blocks of a chilled water fan coil are a fan and a coil, several options and accessories can supplement the design. These include mixing boxes, outside air inlets, hot water/electric heat, silencer/attenuators, filters, etc. Five factors influence which product to choose for a specific application. The factors are:

- Capacity Requirements

- External Static Pressure

- Available Ceiling Space

- Sound Sensitivity

- Outside Air Capabilities

Engineered Comfort offers three types of horizontal units: low profile in-room, high-capacity horizontal, and low profile high-capacity units. Selecting one over the other comes down to the five factors described above.

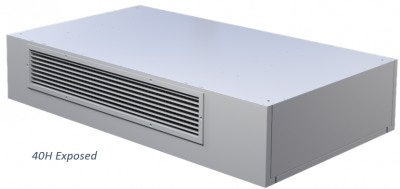

Low Profile In-Room Horizontal Fan Coils

The smallest of the horizontal fan coils is the Low Profile In-Room configuration. Hospitality applications use these small fan coils above the entry corridor of a room. They then supply air directly to the bedroom area. The industry provides four types of these fan coils free return, plenum, telescoping, and exposed. The units above a ceiling use an equally sized access panel that allows easy maintenance. For the five variables introduced above, the units perform as follows:

- Capacity Requirements

- 300-1,500 CFM

- 2/3-3.5 Tons Cooling

- 9-73 MBH Hot Water Heating

- 1-10 KW Electric Heating

- External Static Pressure

- Low, up to 0.5" w.g.

- Motors are pressure dependent

- Low, up to 0.5" w.g.

- Available Ceiling Space

- Concealed Units, 10"

- Exposed Units, 12"

- Sound Sensitivity

- Medium

- Most are unducted causing them to be slightly louder than other options.

- Medium

- Outside Air Capabilities

- Low

- Limited to 4 rows of cooling coil, limits the fan coils ability to handle the latent loads associated with outside air

- Low

In-Room Low Profile units are suited for applications where they supply directly to their intended rooms where there isn't much ceiling space. The unit's small fan(s) cannot handle the static pressure associated with long duct runs or complex air distribution. The plenum version of these units can accommodate ducted supply/return configurations, though care must be given during design not to exceed the .5" static max pressure.

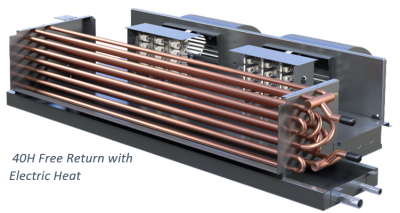

High-Capacity Horizontal Fan Coil Units

High-capacity units provide many more options than their in-room counterparts. The larger units with higher-powered fans enable these fan coils to serve more applications including classrooms, office spaces, conference rooms, industrial spaces, gyms, etc. When measured by the 5 variables their summary is as follows:

- Capacity Requirements

- 400-4,000 CFM

- 1-10 Tons Cooling

- 20-200 MBH Hot Water Heating

- 1-16 KW Electric Heating

- 400-4,000 CFM

- External Static Pressure

- High, up to 0.75" w.g.

- Pressure independent motors available

- High, up to 0.75" w.g.

- Available Ceiling Space

- Sizes 4-24, 17"

- Sizes 30-40, 23"

- Sound Sensitivity

- Low

- Radiated NC 45 and lower

- Low

- Outside Air Capabilities

- Medium

- Up to 6 rows of cooling

- Higher latent load capabilities

- Medium

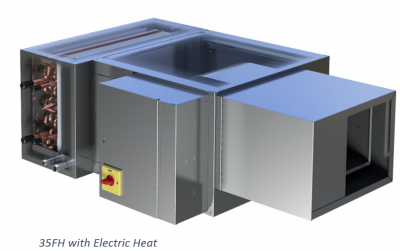

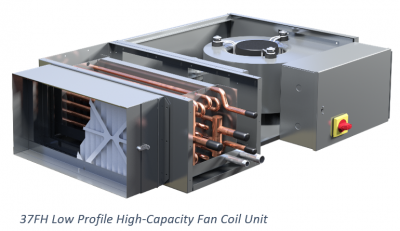

Low Profile High-Capacity Units

A special subset of high-capacity horizontal units are low-profile versions. These products are unique to Engineered Comfort and provide a mix of each version discussed above. When the application has limited ceiling space but requires higher static pressures or cooling capacities, these units are an ideal solution. These have been used in high-end hospitality that has a ducted supply to slots along the windows. Also, office space in Washington DC where floor to floor height is an issue.

- Capacity Requirements

- 100-1,400 CFM

- 2/3-5 Tons Cooling

- 12-80 MBH Hot Water Heating

- 1-8 KW Electric Heating

- External Static Pressure

- High, up to 0.75" w.g.

- Pressure independent motors standard

- High, up to 0.75" w.g.

- Available Ceiling Space

- 11"

- Sound Sensitivity

- Low

- Radiated NC 45 and lower

- Low

- Outside Air

- Medium

- Up to 6 rows of cooling

- Higher latent load capabilities

- Medium

Selections

Using a manufacturer's selection software will aid in the decisions for which product is right for your project. Nailor has software for its Engineered Comfort products, called SelectWorks, that allows you to enter the required capacities, airflows, and design conditions, and the software will show you the options that meet the needs of the project. If you are working on a project and need help with what type to design around or selections, don't hesitate to reach out to us.