In my previous article, located here, I discussed the benefits of selecting a water source heat pump system for your building. The next few articles will discuss how the heat pump works.

The heating and cooling provided by a water source heat pump, and for that matter all refrigerant based conditioning equipment, is made possible by the refrigeration cycle. Mechanical equipment pressurizes and cools refrigerant to achieve the desired temperatures needed to heat or cool the air in a space.

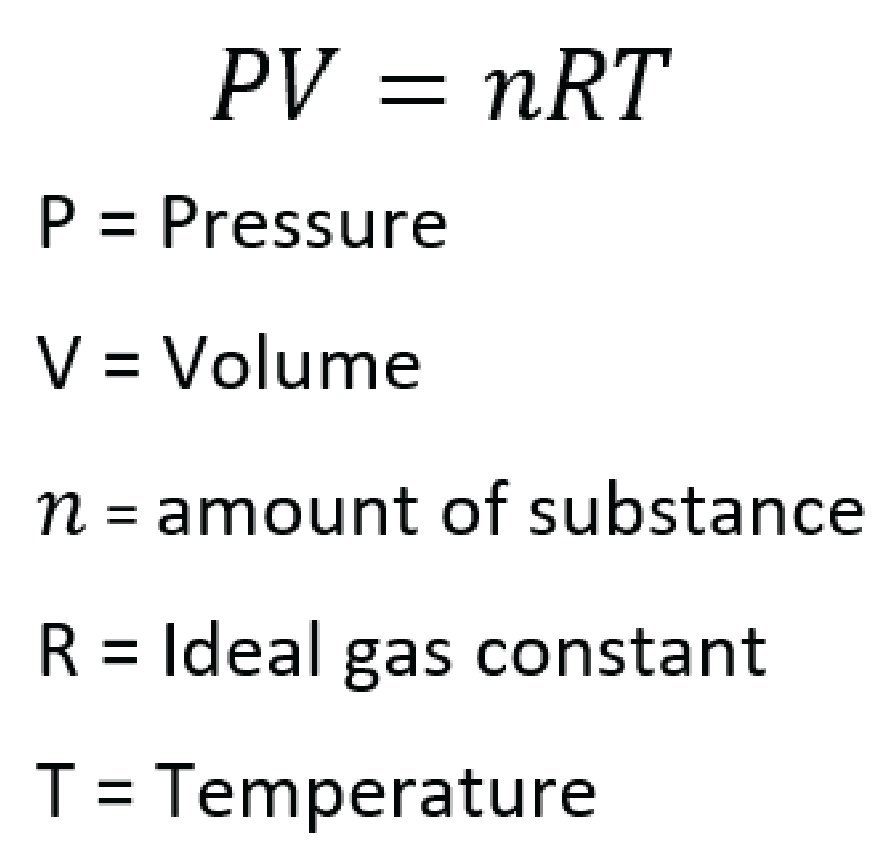

Gas and Liquid substances generally follow the relationships explained by the ideal gas law:

|

|

For this relationship to work, if you have the same volume and you increase pressure the temperature has to increase. If you've ever used canned air to clean your electronics you notice the can and the air cools rapidly as you release the air. Since you're decreasing the pressure, by releasing it from a high pressure can, the temperature is reduced.

These principles are what drives the refrigeration cycle.

Refrigerant

The other enabler of refrigeration is the availability of refrigerants. What makes these substances work as refrigerants is that their boiling point falls within a range that allows it to follow the cycle described below using atmospheric temperatures and relatively low pressures. For commercial and residential heat pumps the most advanced refrigerant used today is R410a. The main benefits of R410a is that it is less harmful to then environment as others, such as Freon (R22), and it is more efficient than R22 because it can absorb and discharge more heat.

The Refrigerant Cycle

The refrigerant cycle includes compression, heat rejection, expansion, heat absorption, and repeat. The is achieved by refrigerants that pass between liquid and gas states during these phases. Because of this, the heat rejection phase is referred to as condensing, a hot gas is rejecting heat and condenses to a liquid during the process. When this liquid is expanded it converts to a gas as it absorbs heat, so this is referred to evaporation.

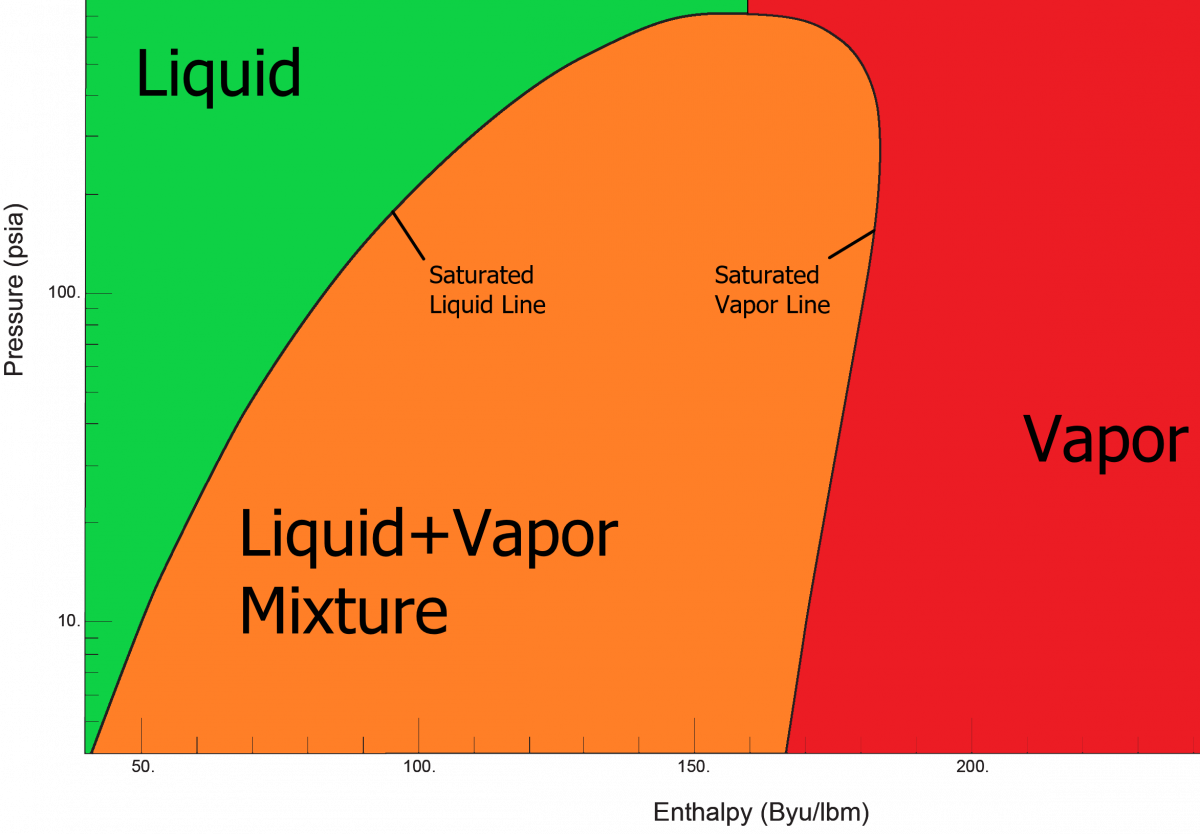

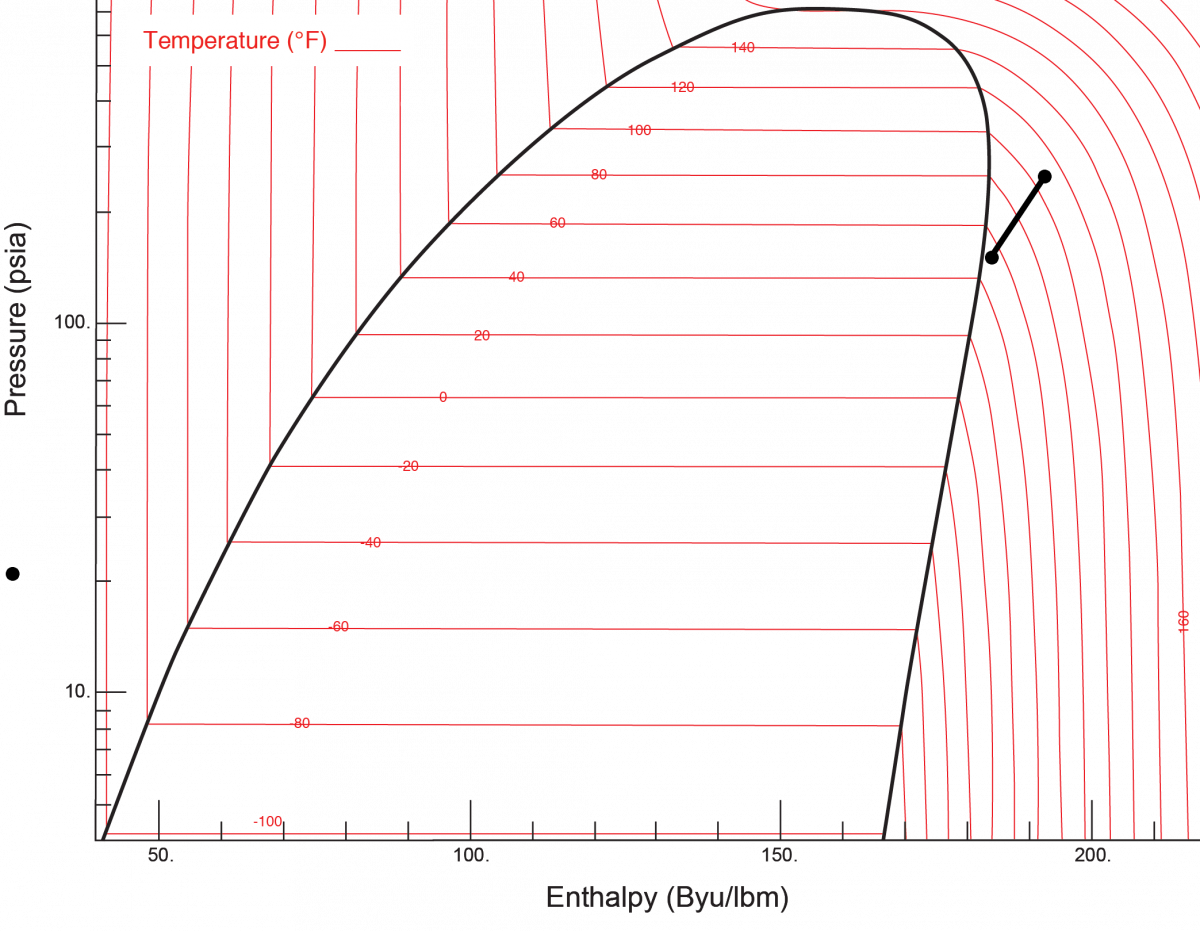

This process can be easily visualized on a Pressure/Enthalpy diagram. Enthalpy is a measure of the amount of heat contained in a substance. Each refrigerant has a specific Pressure/Enthalpy diagram that shows how the substance performs under different pressure and enthalpy conditions. The diagram below shows this relationship for R410a. The green area to the left of the curve represents conditions of pressure and enthalpy that would result in the refrigerant being a liquid. The orange under the Pressure Enthalpy curve is when the refrigerant is in a transition state, a mixture of gas and liquid. The red area to the right of the curve is when the refrigerant is 100% gas. At the pressure & enthalpy points on this line the refrigerant will be 100% liquid, on the left hand side, or 100% vapor, on the right hand side, these are called the saturated liquid/gas lines.

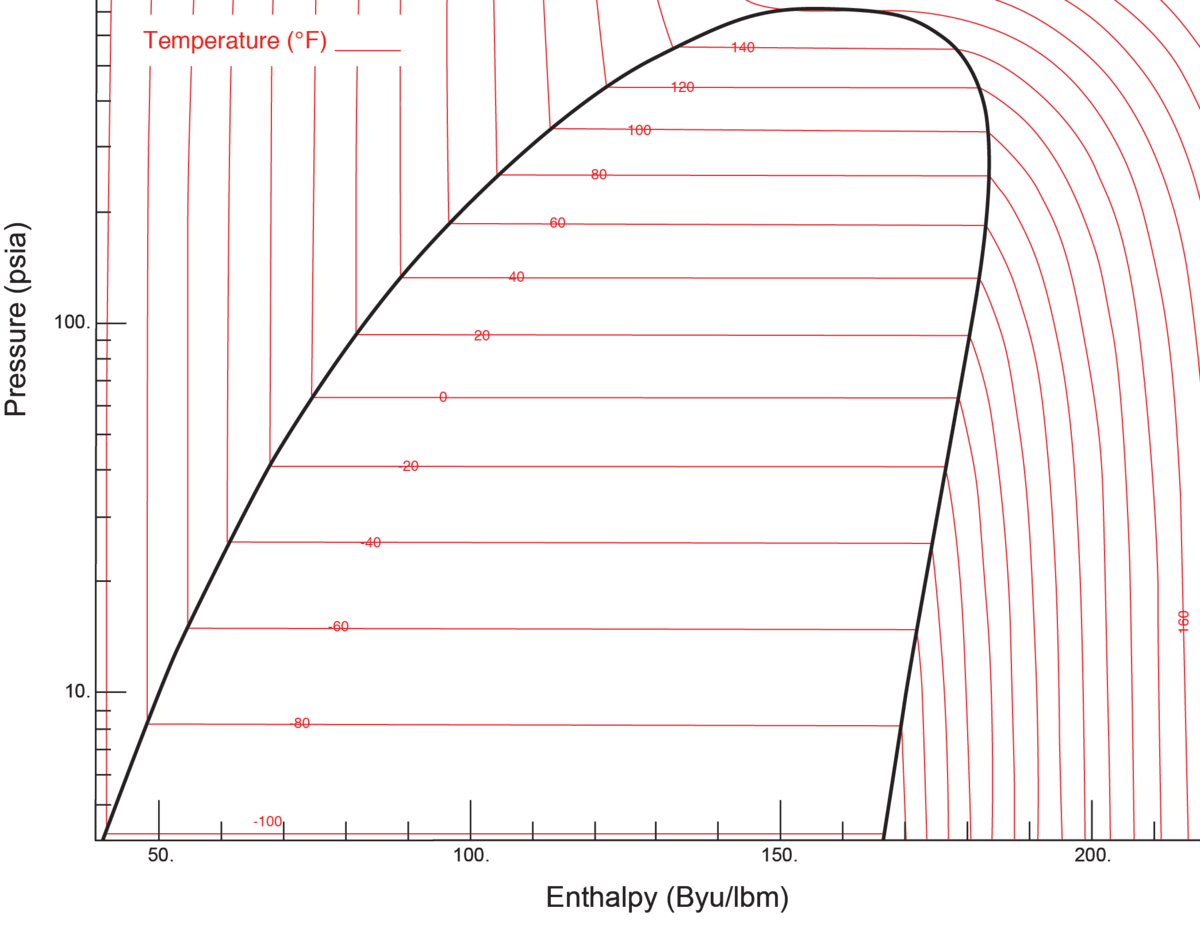

If you add constant temperature lines to the graph, as shown below in red, you see that in the transition zone for a given pressure the temperature remains the same as the refrigerant accepts/rejects heat, until it reaches the saturation line. This is a very important concept in thermodynamics and, based on personal experience, you cannot pass Thermodynamics 101 at Texas A&M without understanding this.

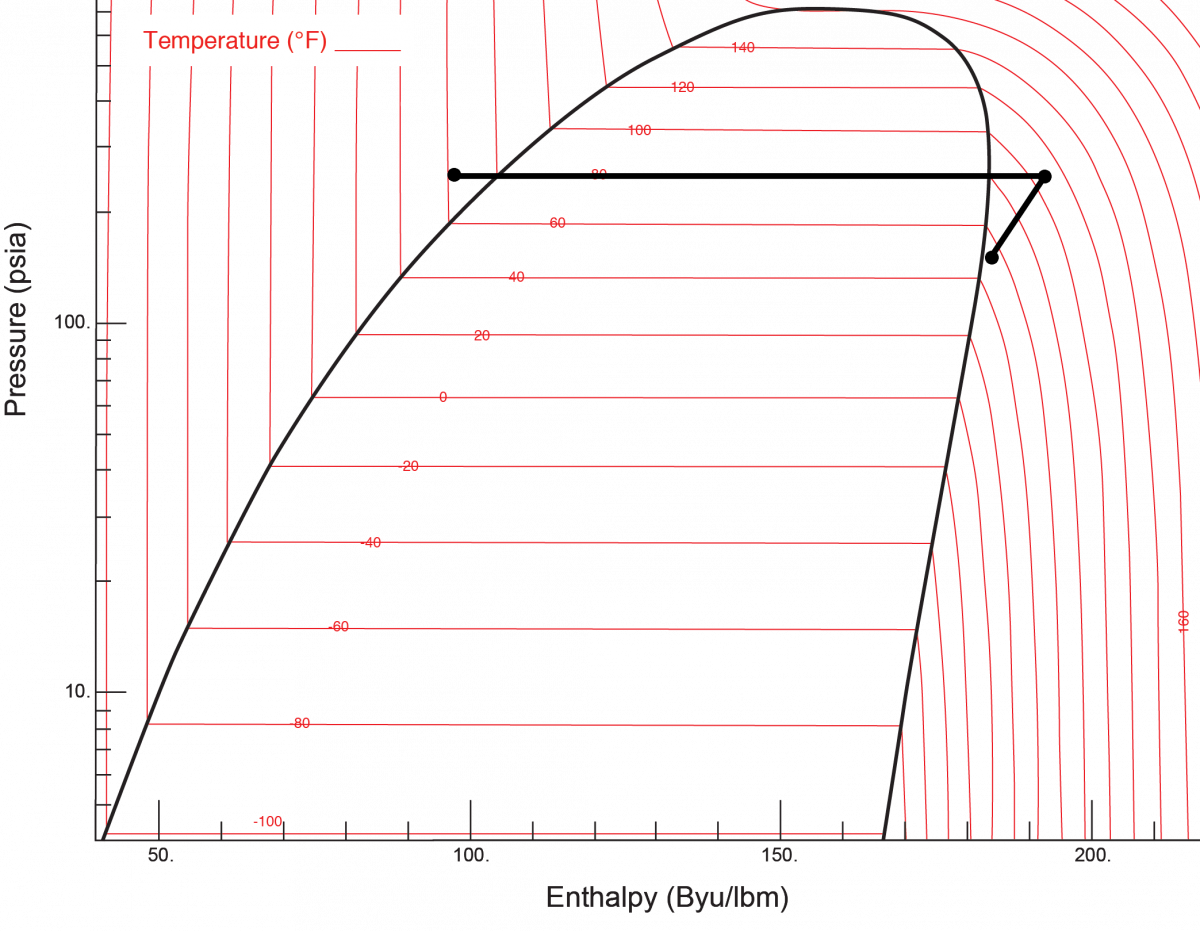

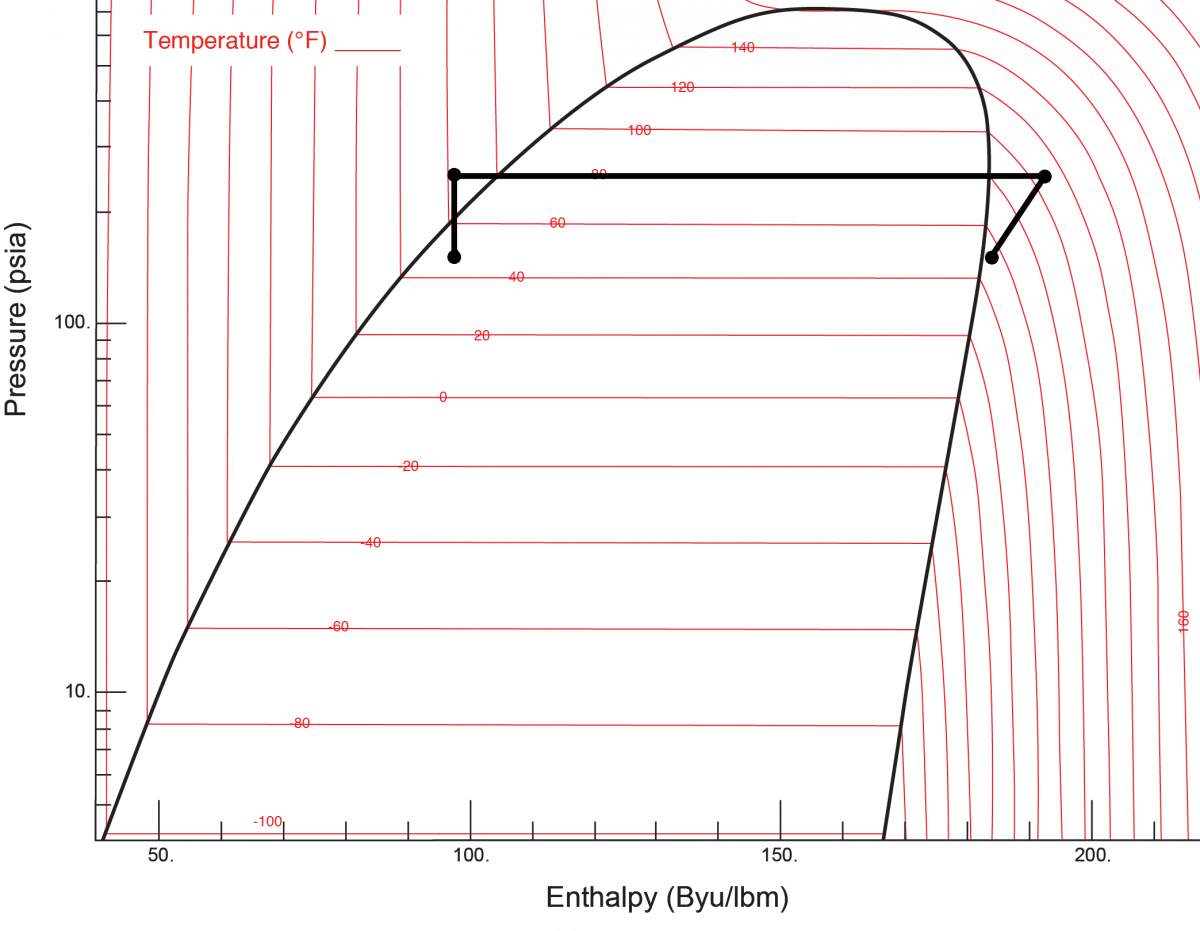

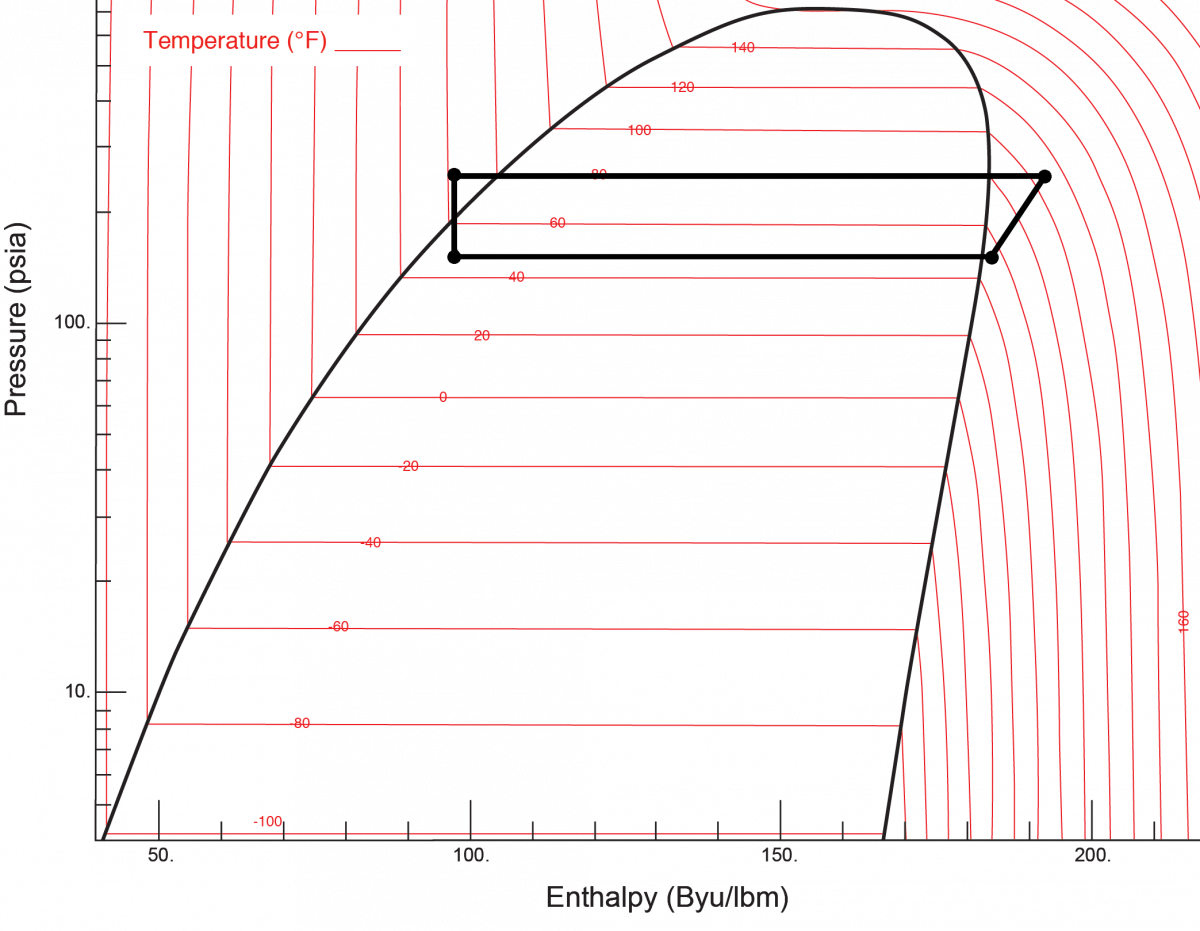

Using this diagram we can map out the refrigeration cycle for R410a. Nailor and Engineered Comfort are in the final stages of testing our Serenity Water Source Heat Pump product line and I have used the temperatures and pressures measured in the cycle using R410a.

Refrigeration Map

-

Starting with the compression phase on the cycle, the low-pressure low temperature gas is compressed to a high pressure, high temperature gas. As you see, the increase in pressure increases the temperature as would be expected by the gas law shown above.

2. The high-pressure high temperature gas then enters a phase of heat rejection. The temperature of the gas goes down until it reaches the saturated gas line and then the temperature remains the same in the transition zone, and then ultimately gains some sub-cooling past the liquid saturation line. The refrigerant is now a liquid.

3. The high-pressure low temperature liquid is then expanded rapidly by an immediate reduction of pressure. This drives the pressure and temperature downward. As you can see, this is driven down to ~52º which is close to the target of 55ºF design leaving air temperature.

4. The low temperature low pressure gas/liquid mixture absorbs heat until it reaches and passes the saturation line, becoming 100% gas and ready for compression.

Summary

This is the general cycle that refrigeration goes through to reject and absorb heat. This cycle can be used to cool or heat a space. Understanding this cycle and the concepts presented will allow you to understand the equipment being specified, selected, and ultimately employed within your project.