Nailor offers a comprehensive line of damper products for airflow control in commercial and industrial HVAC systems. Our Wind Tunnel & Damper Testing Laboratory has established the company as an industry leader for testing our products to the latest version of AMCA, UL, ANSI, and other industry standards of performance.

taxonomy-1586,taxonomy-1587,taxonomy-1653,taxonomy-1588,taxonomy-1458,taxonomy-1590,taxonomy-1591,taxonomy-1592,taxonomy-1593,taxonomy-1585

Models 1010, 1020, 1012, 1022, 1090 and 1091UT

For use in low to medium velocity and pressure commercial HVAC systems. Galvanized, aluminum, Type 304 stainless steel optional. Variety of electric two position, modulating, and pneumatic factory actuators available.

Models 1110, 1120, 2010, and 2020

Nailor high performance control dampers are ideal for use in high velocity, medium pressure commercial and industrial HVAC systems. Standard features include a rugged galvanized steel hat channel frame with superior structural strength, no-maintenance concealed linkage located out of the airstream, totally enclosed within the damper frame, and heavy duty airfoil blades that combine superior rigidity and deflection resistance with low pressure drop. Extruded aluminum airfoil blade models with optional insulated blades and/or frame available.

Models 2200TB and 2200TBF

The 2200 Series are high-performance, low-leakage control dampers designed with a thermally broken concept to minimize thermal transfer and reduce condensation. The 2200TB model features thermally broken blades, while the 2200TBF model includes both thermally broken blades and frame for enhanced energy efficiency. These dampers are engineered to meet the requirements of the International Energy Conservation Code (IECC), making them ideal for applications where energy conservation and thermal performance are critical.

Models AMD-TD-10, AMD-TD-20

Highly accurate and responsive Air Measuring Control Dampers use thermal dispersion probes and control dampers that continuously read and control the airflow. These units reduce energy and maintenance costs, improves indoor air quality, and aids in ASHRAE 62.1 compliance. The AMD series may be used in any commercial ducted application, with common applications being outside air intake and floor supply/return tracking. The rugged and hermetically sealed probes boast 2% sensor accuracy and aerodynamic apertures that straighten the airflow for an improved reading. Featuring an easy to read, back-lit, color display and intuitive, menu-driven interface, the Electra- flo transmitter has BACnet MS/TP and Modbus RTU communication capabilities that allow for remote monitoring and operation.

Models 1510, 1517, 1520, 1527, 1530, 1537, 1540, and 1547

Nailor 1500 Series Heavy Duty Control Dampers feature heavy duty galvanized steel U-channel frames, adjustable face linkage, and stainless steel pivot pins which results in smooth operation and easy maintenance. Designed for "in-duct" mounting applications to control airflow and provide positive shut-off. Dynamic limitations: Pressure: 2.9-20.1" w.g. and Velocity: 3000-3500 fpm (Vee Blade Models) and Pressure 10.0-32.0" w.g. and Velocity: 4000-6000 (Airfoil Blade Models)

Models 1810, 1820, 1870, and 1890

Nailor Balancing Dampers are ruggedly built and designed for manual balancing applications. They are a cost effective and reliable damper for reduced volume control and offer an economical manufactured product alternative to custom ‘shop built’ dampers. Not intended for use in shut-off or actuated applications.

Models 1370 and 1380

The backdraft dampers in this series are gravity operated and are for use in light, medium and heavy duty commercial or light duty industrial HVAC applications. They allow airflow to pass in one direction and to prevent it in the opposite direction. They are constructed from corrosion resistant extruded aluminum.

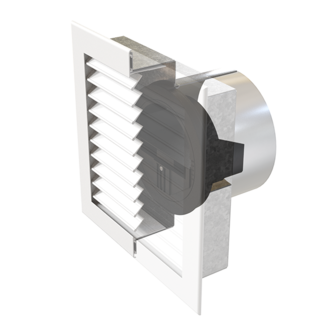

Models 1370CB, 1380CB, and 1390CB

Standard and high performance counterbalanced backdraft dampers are designed to automatically prevent the backflow of air while allowing for automatic air intake or exhaust/pressure relief in medium duty and heavy duty commercial and light industrial HVAC applications are available. Corrosion-resistant extruded aluminum construction highlights the model’s features, which include a reinforced mitered corner frame that resists racking and aerodynamic blades that overlap the jambs for maximum weather protection. Extruded PVC blade seals provide quiet closure as well as extra weather protection.

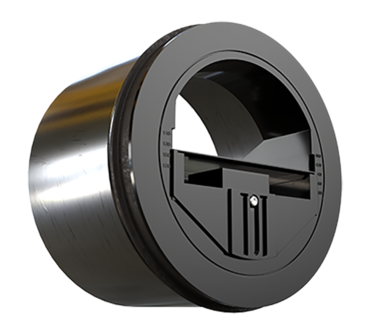

Model Series CVR

The CVR constant volume regulator is an extremely cost-effective way to precisely control the airflow of the HVAC systems – especially high rise buildings - without the need for on-site electric or pneumatic controls or sensors. A self-regulating blade and spring piston adjust automatically to maintain a constant set airflow volume. They adjust automatically for variable duct pressures caused by building pressure, thermal stack effect, dust buildup and other variable adverse conditions.