One of the most important factors in selecting any piece of HVAC equipment is energy efficiency. In my previous article I discussed how the critical components of the WSHP works to deliver conditioning to the space. Here I’ll discuss how energy efficiency is calculated, tested, and communicated along with measures that providers can take to increase the efficiency of their product.

Energy efficiency is the measure of how much cooling/heating you get for each unit of energy put into the equipment. More efficient equipment utilizes less energy for the same amount of conditioning and therefore costs less to operate. Water source heat pumps use two units of efficiency for communicating their performance: Energy Efficiency Ratio (EER) and Coefficient of Performance (COP) for heating.

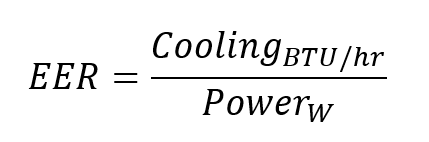

EER

Energy Efficiency Ratio is the total amount of cooling divided by the total amount of power used:

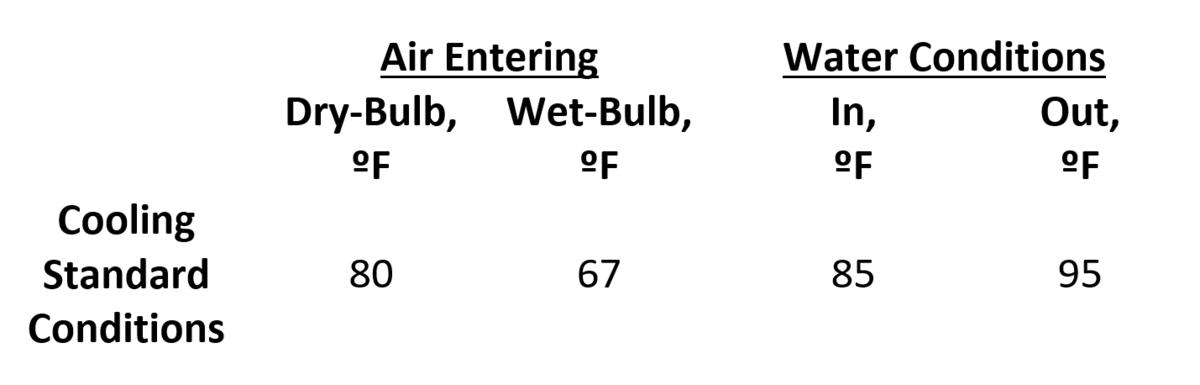

he amount of cooling is measured in BTU/hr and the power is measured in watts. These measurements and the ultimate rating are governed by a standard AHRI 340/360 Performance Rating of Commercial and Industrial Unitary Air-conditioning and Heat Pump Equipment. The AHRI standard provides testing requirements such as standard conditions, testing equipment, and procedures. For a water source heat pump the standard conditions for cooing are as follows:

AHRI has standardized the conditions for testing and communicating a unit’s energy efficiency so that equipment specifiers can compare all equipment at the same settings.

To run the test, the air entering the heat pump is set to the required 80ºF dry bulb and 67ºF wet bulb. Also, the water entering the heat pump heat exchanger is set to 85ºF. During the test, the flow rate of the water through the heat exchanger is controlled to achieve a leaving water temperature equal to the 95º required by the standard.

During the test, the flow rate and temperature of the leaving air is measured to determine the amount of cooling provided by the unit. The amount of power used to generate this cooling is also measured. Both numbers combine to calculate the EER using the equation shown above. To be AHRI certified, AHRI must be able to recreate the stated ratings in their test set up.

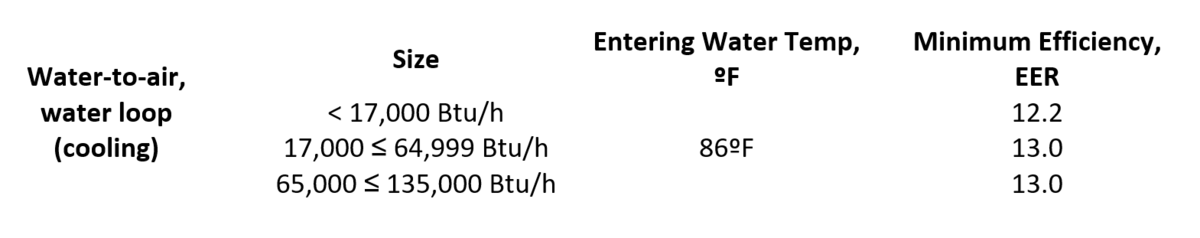

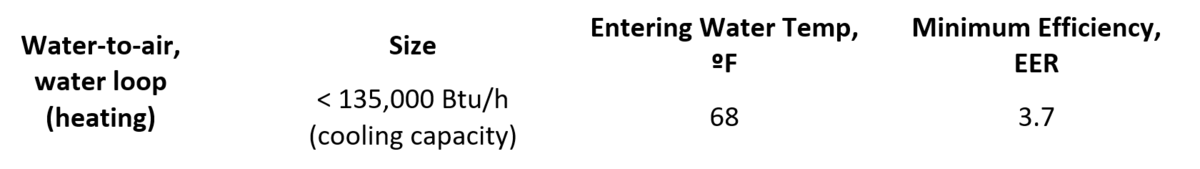

ASHRAE designates the minimum energy efficiency for equipment through their ASHRAE 90.1 standard. For water source heat pumps, utilizing a building water loop, it requires a minimum efficiency based on the size of the equipment:

Using the test procedure and settings described above the equipment must be able to meet the minimum efficiency listed above to be utilized in the US.

COP

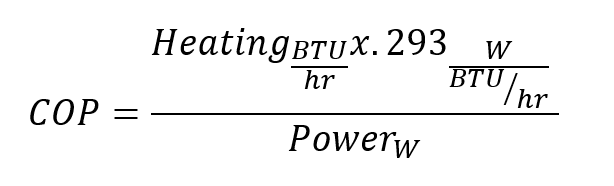

For heating the standard metric for energy efficiency is Coefficient of Performance (COP):

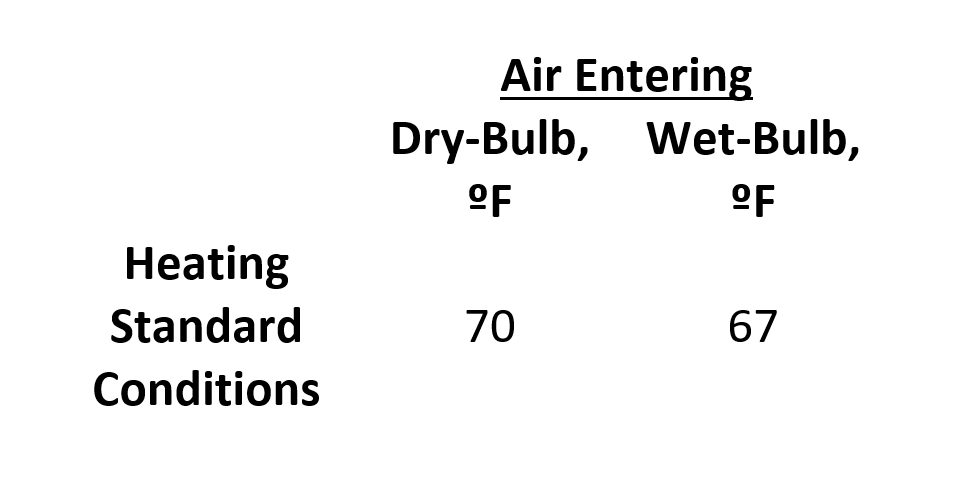

COP and EER are fundamentally the same measurement, the COP is just calculated in W/W rather than Btu/hr/W. The heating mode test is performed in the same manner as the cooling test, but the entering air and water temperatures are modified to more closely match what is experienced by the unit when it is in heating mode. From the AHRI standard the conditions to be used for the heating energy efficiency test are as follows:

ASHRAE then requires the entering water temperature to be 68ºF, based on these conditions the unit must meet the minimum heating performance of:

Even at the minimum requirement, a heat pump is extremely efficient when it comes to heating. At a COP = 3.7, a heat pump provides 3.7 watts of heat for every watt of energy used to create that heat. Electric heat is considered 100% efficient, which means that 1 watt of heating takes 1 watt of energy. Gas heat efficiency is measured in Annual Fuel Utilization Efficiency (AFUE) and is considered extremely efficient at 95%, which is less than the 100% of electric heat.

Increasing Efficiency

With the equation for efficiency being amount of conditioning over the amount of energy, there are two ways to increase the efficiency of the unit. Either you can increase the amount of conditioning or decrease the amount of energy used.

Heat Transfer

Increasing the conditioning capacity of a system comes down to providing higher heat transfer in the system. The challenge is to achieve more heat transfer without an increase in energy used. The two phases of the refrigeration cycle in a heat pump are done in the coil and the heat exchanger. In cooling, if the coil transfers more heat it will cool more air for the same amount of effort. A few examples of this would be to increase the fins/inch on the coil, increase the thickness of the coil, or increase the overall size of the coil. All of which increase the surface area for contact between the coil and the air. The concern with these efforts is the increase in static pressure, and therefore fan energy that is required to overcome these efforts. Also, larger coils cost more and could cause the unit to be unprofitable.

In the heat exchanger, increasing the surface area contact between the water and refrigerant will increase heat transfer as well. This can be done by rifling the inner copper tube in the heat exchanger or providing a larger heat exchanger.

Energy Use

Fans

The two largest consumers of electricity in the water source heat pump are the compressor and the fan. The way to increase the efficiency on the fan is to focus on the motor and how it is controlled. In HVAC fans there are two types of motors: Permanent Split Capacitor (PSC) and Electronically Commutated (ECM). A PSC motor is about 45% efficient and maintains the same efficiency regardless of the speed of the motor, which can only be modified at set speed ranges. The ECM is 75% efficient and can operate at variable speeds, becoming more efficient at lower speeds. Choosing an ECM motor further reduces the energy used on the unit.

The two largest consumers of electricity in the water source heat pump are the compressor and the fan. The way to increase the efficiency on the fan is to focus on the motor and how it is controlled. In HVAC fans there are two types of motors: Permanent Split Capacitor (PSC) and Electronically Commutated (ECM). A PSC motor is about 45% efficient and maintains the same efficiency regardless of the speed of the motor, which can only be modified at set speed ranges. The ECM is 75% efficient and can operate at variable speeds, becoming more efficient at lower speeds. Choosing an ECM motor further reduces the energy used on the unit.

Compressors

For compressors there are three different choices reciprocal, rotary, and scroll.

Reciprocating Compressors

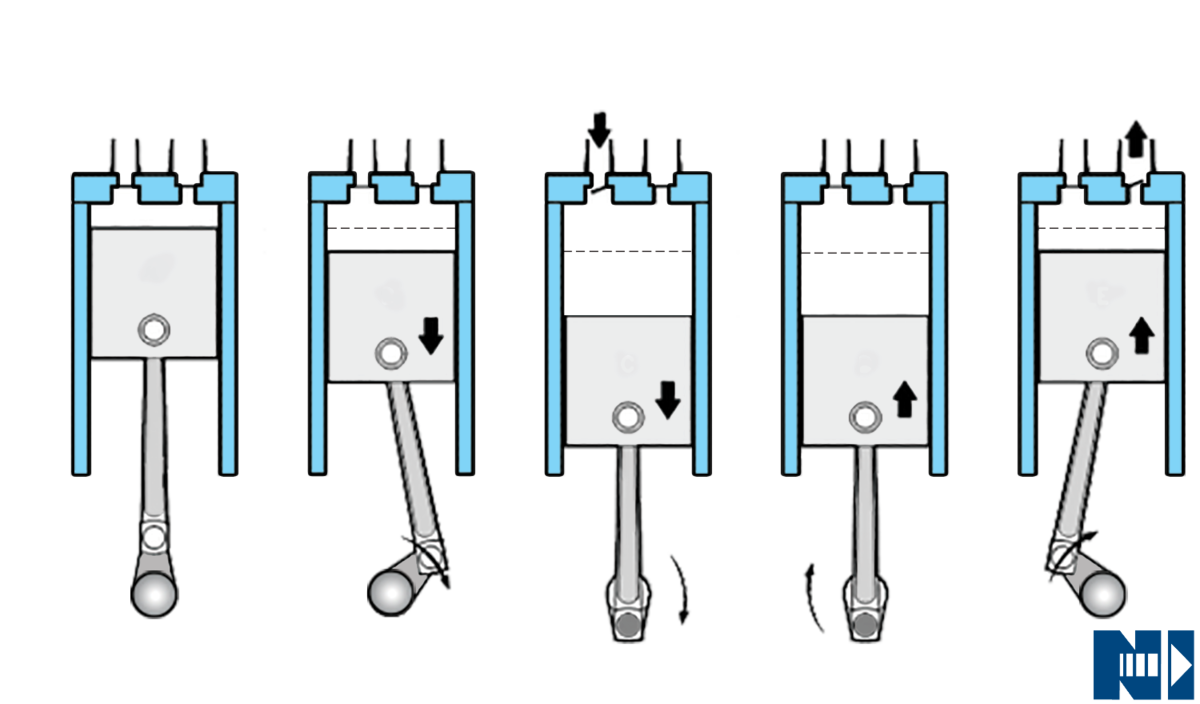

Reciprocating compressors operate like the piston and cylinder in your car. A piston reciprocates within a cylinder, drawing in the substance to be compressed and then compressing the substance to a specific pressure. Once the pressure is achieved the discharge valve on the compressor will open and the compressed substance is expelled. The benefit of reciprocating compressors is their low cost to purchase. Though, they have the lowest energy efficiency for several reasons:

- Compresses one volume at a time

- Has a large clearance volume, which is compressed refrigerant that remains in the compressor after a cycle. This wastes the energy it took to compress it.

- Requires an inlet and discharge valve that both use energy

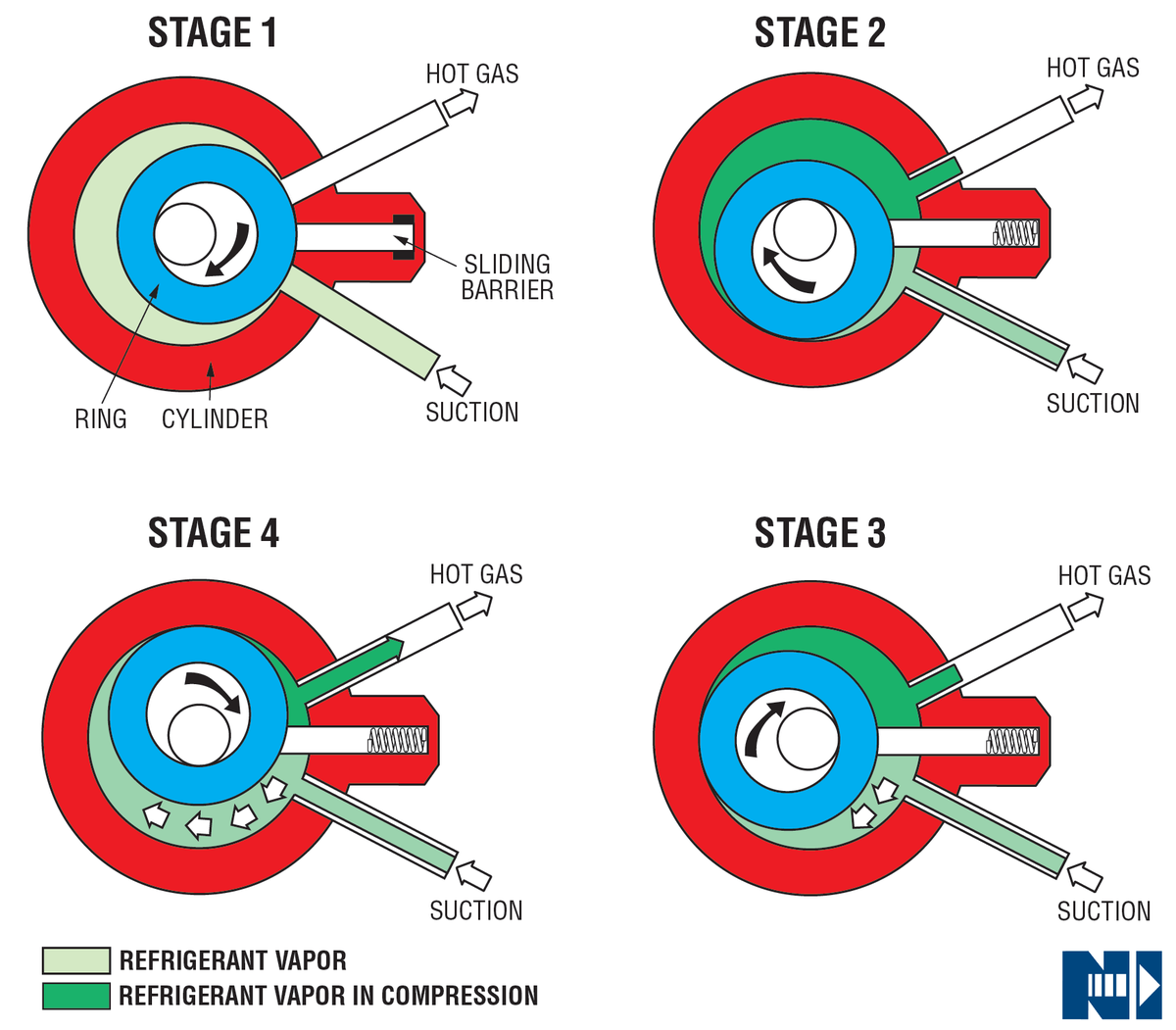

Rotary Compressor

Rotary compressors are characterized by a ring that rotates eccentrically within a cylinder to continuously draw and compress a substance. The compressor has a sliding barrier that separates the intake and compression areas of the cylinder. Once the substance is fully compressed a discharge valve opens to allow it to move to the next stage of the cycle. The rotary compressor provides some advantages over the recciprocating compressor with regards to energy efficiency:

- Continuously intakes refrigerant while compressing

- Only has one valve that operates and utilizes energy

- Has a smaller clearance volume

This is the most efficient option for HVAC equipment up to 1 ton of cooling. The Serenity Water Source Heat Pump product line utilizes rotary compressors up for its 09 and 12 sizes.

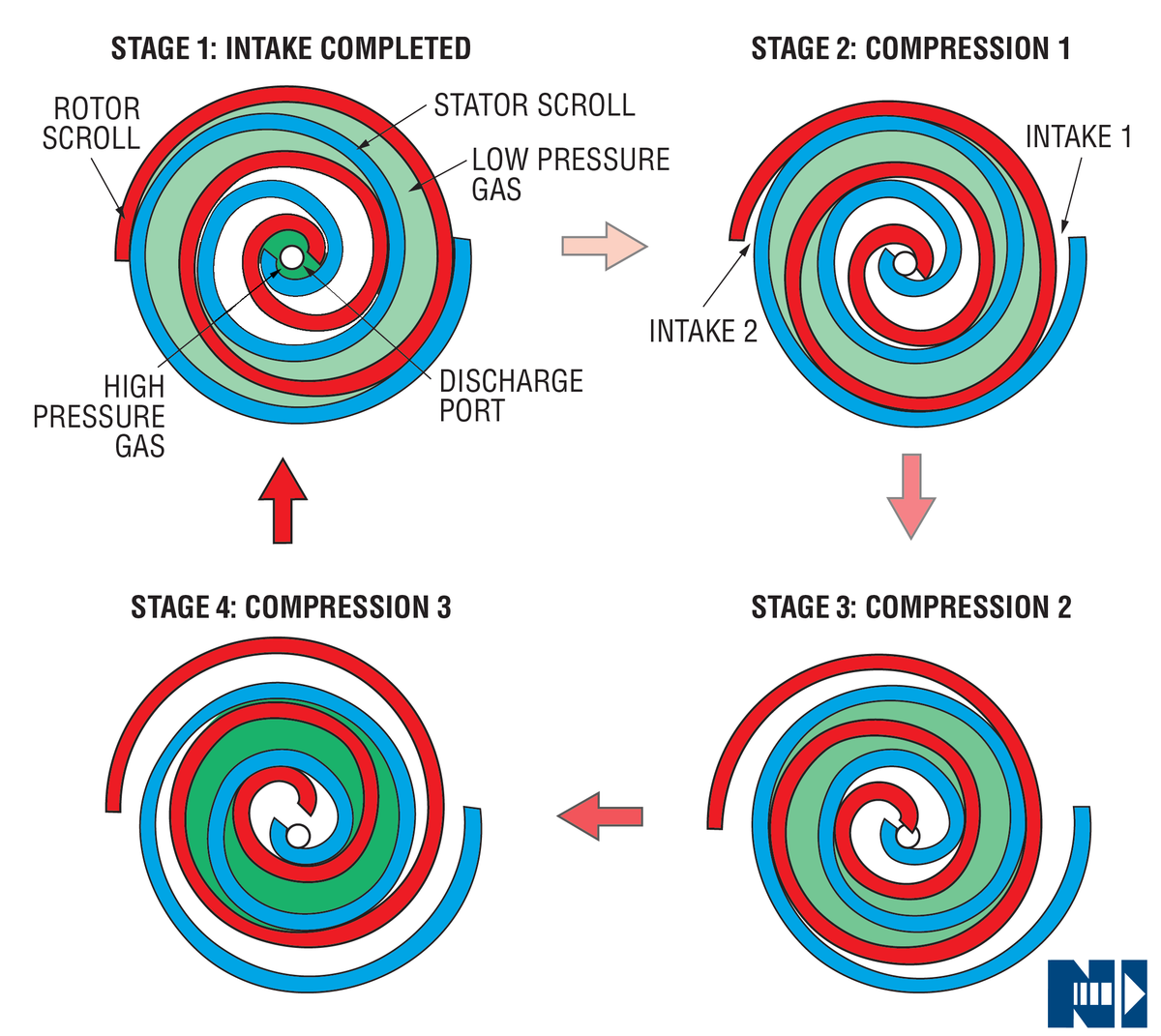

Scroll Compressor

Scroll compressors are characterized by a spiral that rotates within another matching spiral. This allows two volumes of a substance to be continuously drawn in and compressed. When the refrigerant reaches the center of the spirals it has reached its full compression and moves to the next phase of the cycle. This is the most efficient compressor on the market for the following reasons:

- No clearance volume

- No valves

- Two volumes are compressed at one time

Scroll compressors are only available down to 1.5-ton sizes and the Serenity Heat Pumps 1.5 ton and above utilize scroll compressors.

The Complete Package

To deliver the most efficient heat pump a provider must select all these technologies along with their costs to balance the efficiency with the price the market can bear. Nailor Industries has utilized its 50 years of HVAC knowledge to build a portfolio of water source heat pump products that are second to none. Starting from scratch has allowed Nailor to provide the most energy efficient product portfolio on the market, providing an attractive balance of cost and performance perspective.