Most people are familiar with a standard residential split air conditioning system. It is split because the indoor system blows the cooled or heated air and the outdoor unit makes a lot of noise when it’s operating. These two pieces of equipment are connected by piping that carries refrigerant between them. The outdoor unit contains a compressor, outdoor coil, and fan. During cooling the compressor will compress the refrigerant into a superheated gas, then force it through the outdoor coil. The fan draws the outside air through the coil so that the superheated gas cools. The refrigerant flows to the indoor unit that rapidly expands the high pressure cooled liquid to create a low-pressure low temperature gas that enters the indoor coil and the indoor fan draws air across it to cool the space. After cooling the air, the low pressure warmed refrigerant gas goes back to the compressor to start the process over again.

A residential heat pump can switch the flow of the refrigerant so that the superheated compressed gas flows to the indoor unit to heat the space. A water source heat pump (WSHP) performs the same operation, it just moves the compressor into the indoor unit and replaces the outdoor coil with a heat exchanger that uses a building loop of water instead of the outside air.

My previous article, located here, discusses the refrigerant cycle used to heat or cool a space using a heat pump. This article will describe the components in a heat pump and show how they execute the refrigeration cycle.

A water source heat pump has the following components:

- Compressor

- 4-Way Reversing valve

- Refrigerant-Water Heat Exchanger

- Thermal expansion device

- Coil

- Fan

Each of these components work together to efficiently perform the refrigeration cycle and condition the space.

Compressor

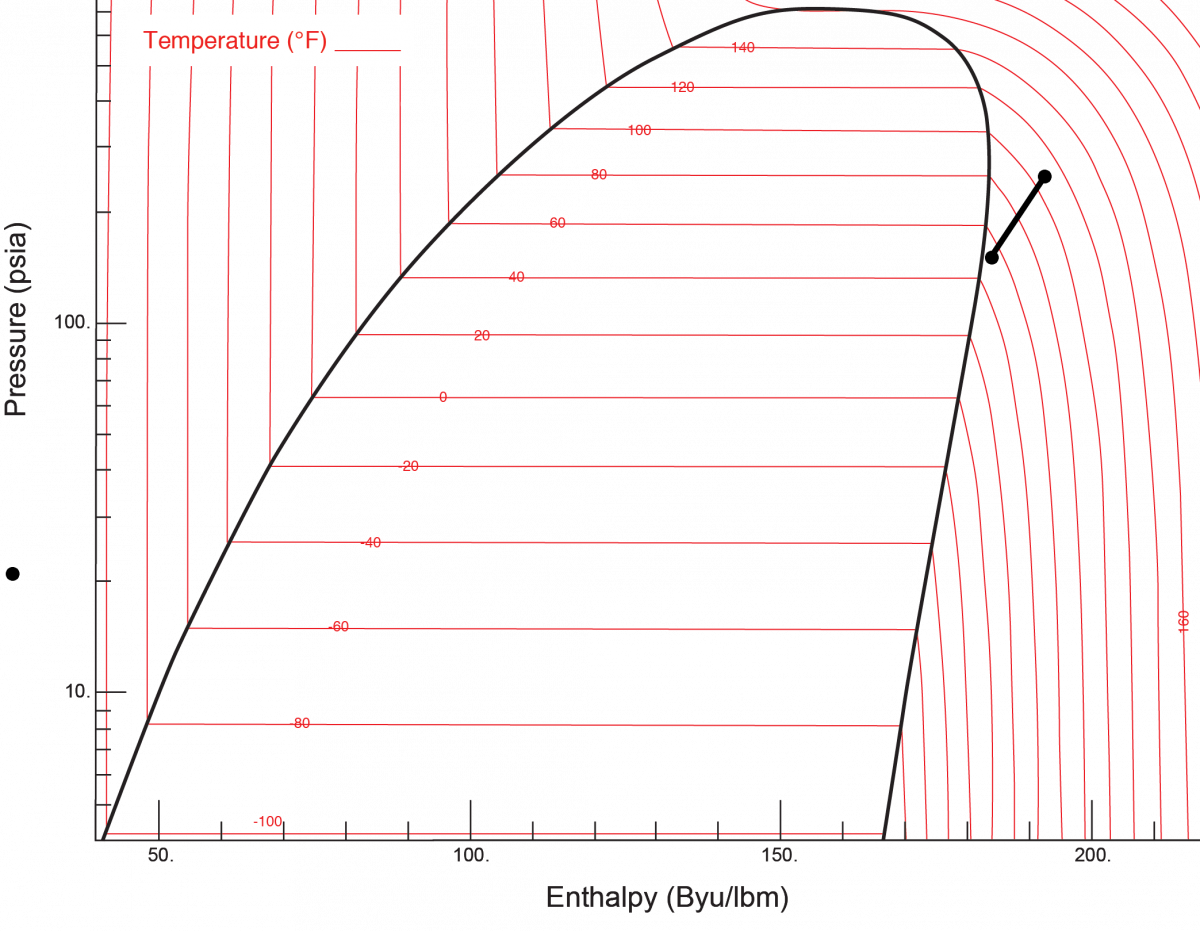

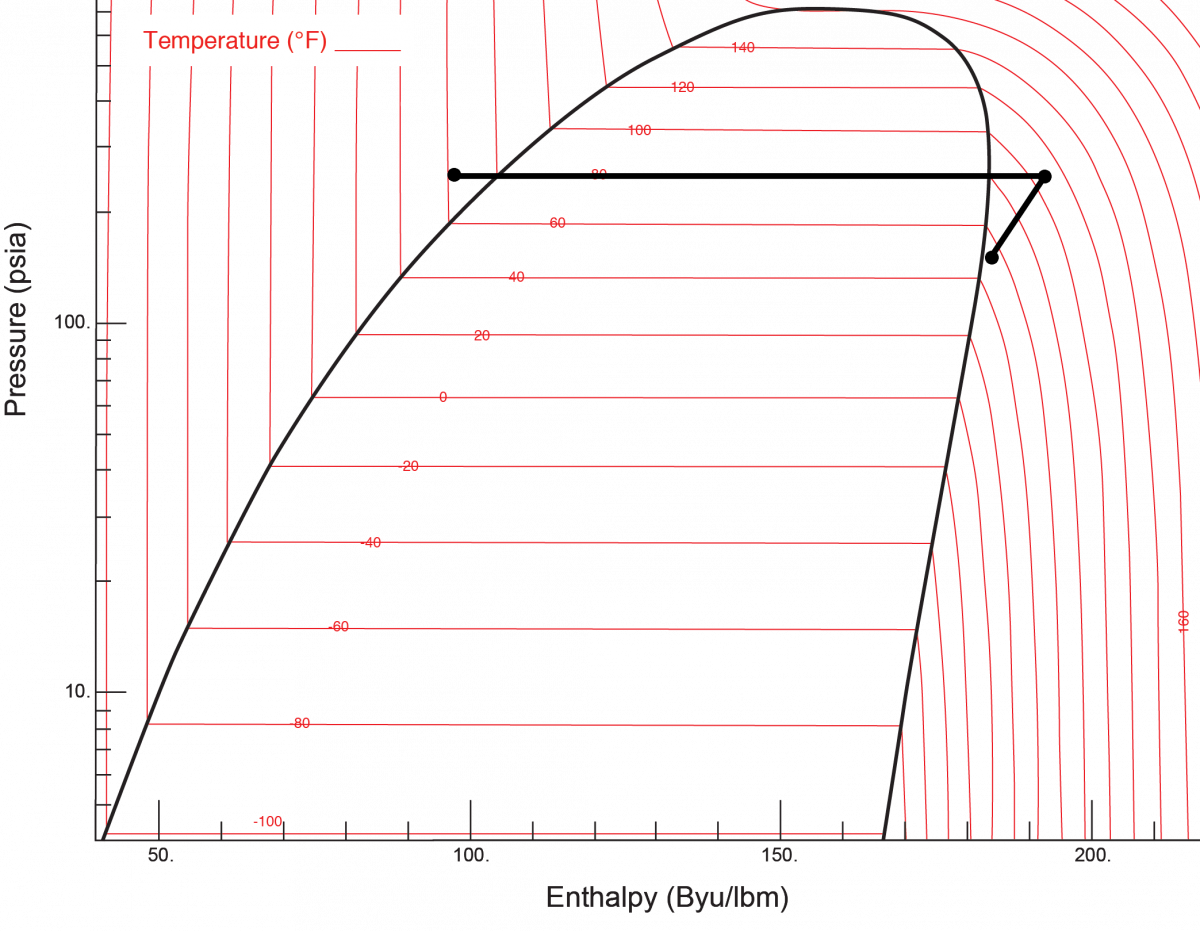

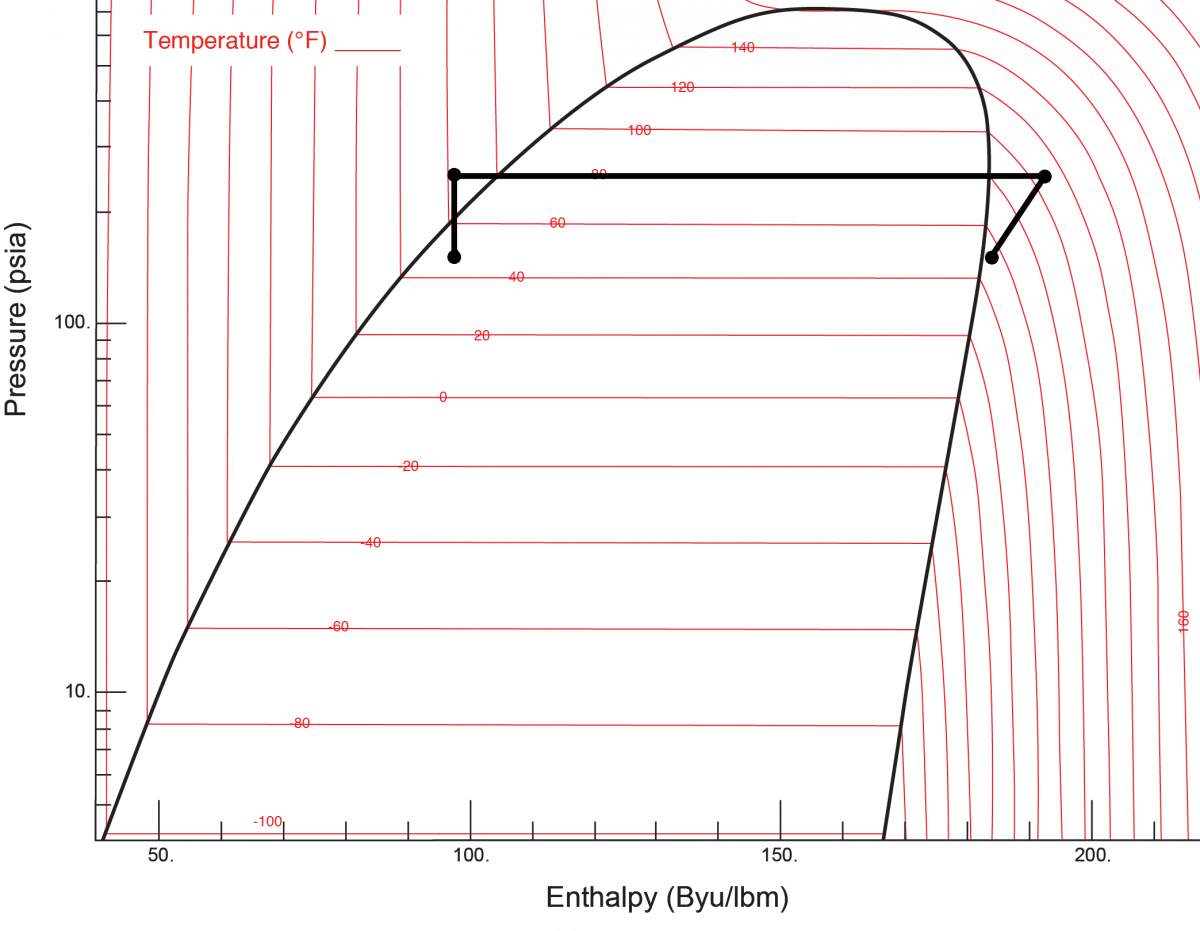

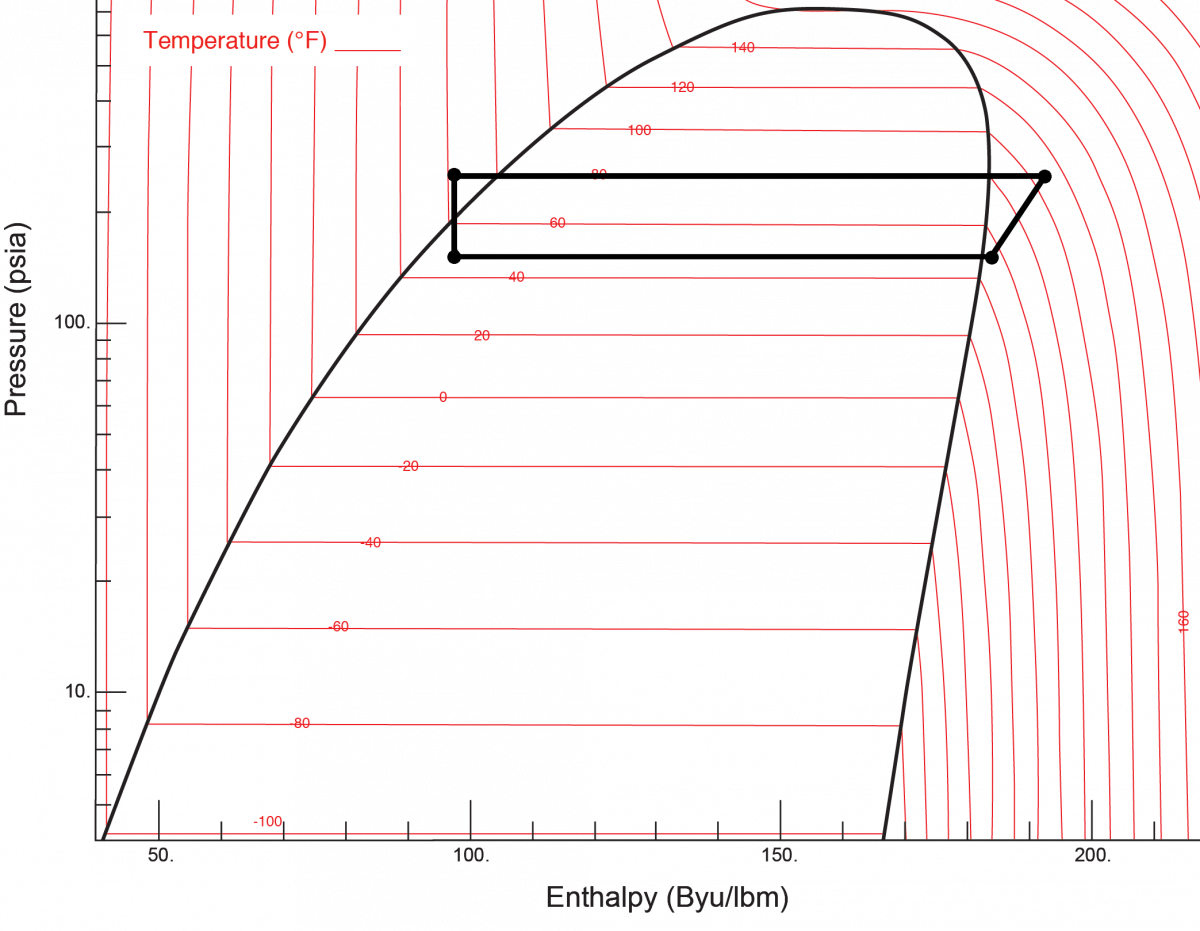

The compressor is the heart of the WSHP. It powers the refrigeration cycle by forcing the refrigerant through the heat pump, either cooling or heating the space depending on the call from the thermostat. For the purposes of this article, it is the first stage of the refrigeration cycle. The compressor pressurizes a medium temperature refrigerant gas into a high-pressure high temperature superheated gas. This is represented on the Pressure Enthalpy (PE) chart shown below.

For most of the water source heat pumps used today, the compressor is either rotary or scroll in design. They just use two different geometries to achieve this.

Rotary Compressor

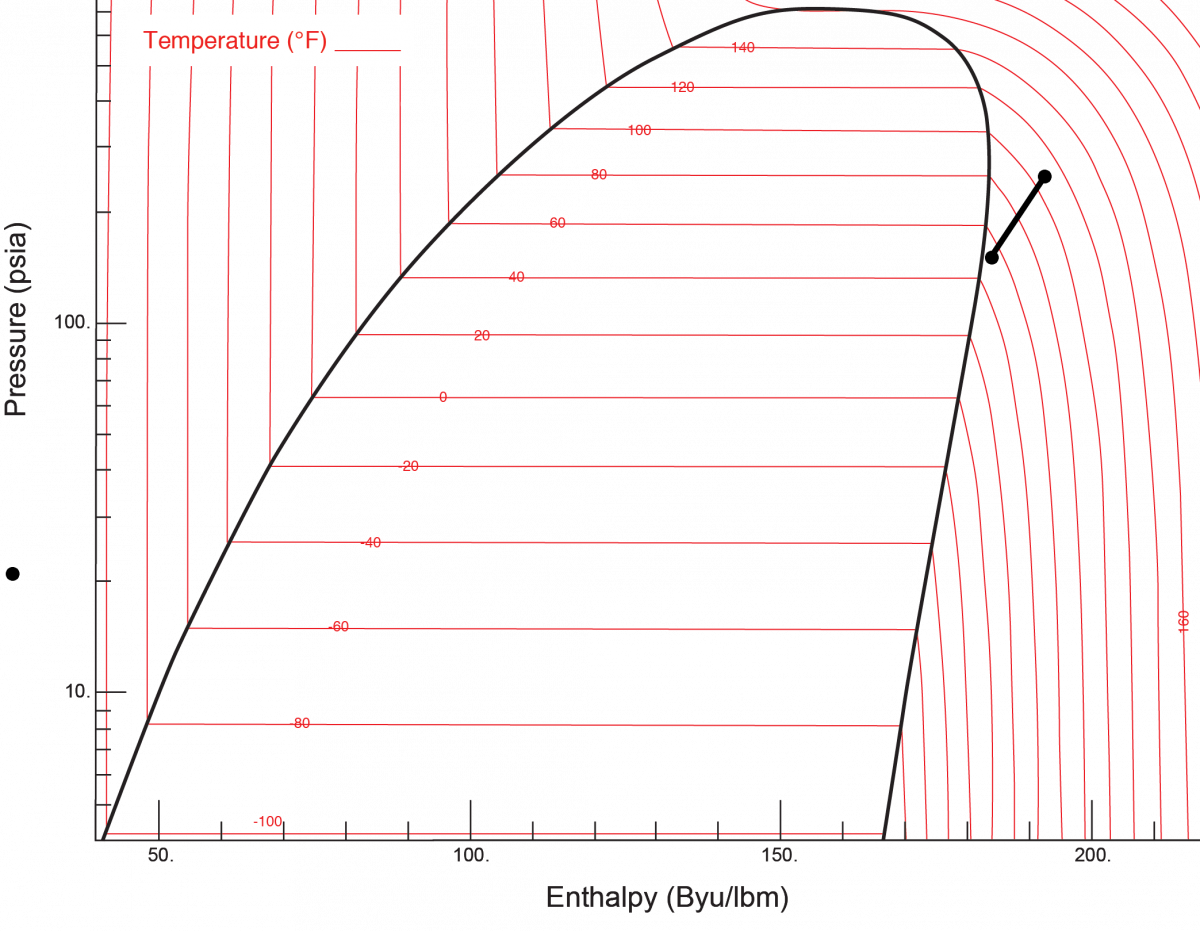

Most water source heat pumps on the market that are lower than 2 tons of cooling capacity use a rotary compressor. A rotary compressor is characterized by an electric motor that turns an offset ring inside of a cylinder that continuously draws in refrigerant and then compresses it. The stages of compression are shown in the graphic below:

The parts of the rotary compressor are the cylinder (stator), ring (rotor), sliding barrier, suction connection (inlet), and the hot gas connection (outlet). At Stage 1, the volume between the cylinder and the ring is fully occupied by low pressure warm refrigerant. As the ring starts to rotate towards Stage 2, the refrigerant will start to compress. In the hot gas discharge, there is a valve that holds the refrigerant in the compressor until a certain pressure is realized. Low pressure gas from the suction line will start to enter the compressor as the ring rotates as well. The sliding barrier will move to keep contact with the ring and separate the high pressure and low-pressure gases. Moving from Stage 2 to Stage 3 the refrigerant continues to be compressed while more low-pressure gas is drawn into the compressor. At stage 4, the gas has reached full compression and the discharge valve opens to allow it to move into the hot gas line of the refrigerant cycle. Just after the release of the fully compressed gas, the compressor returns to its position in stage 1 and the process starts over again.

Scroll Compressors

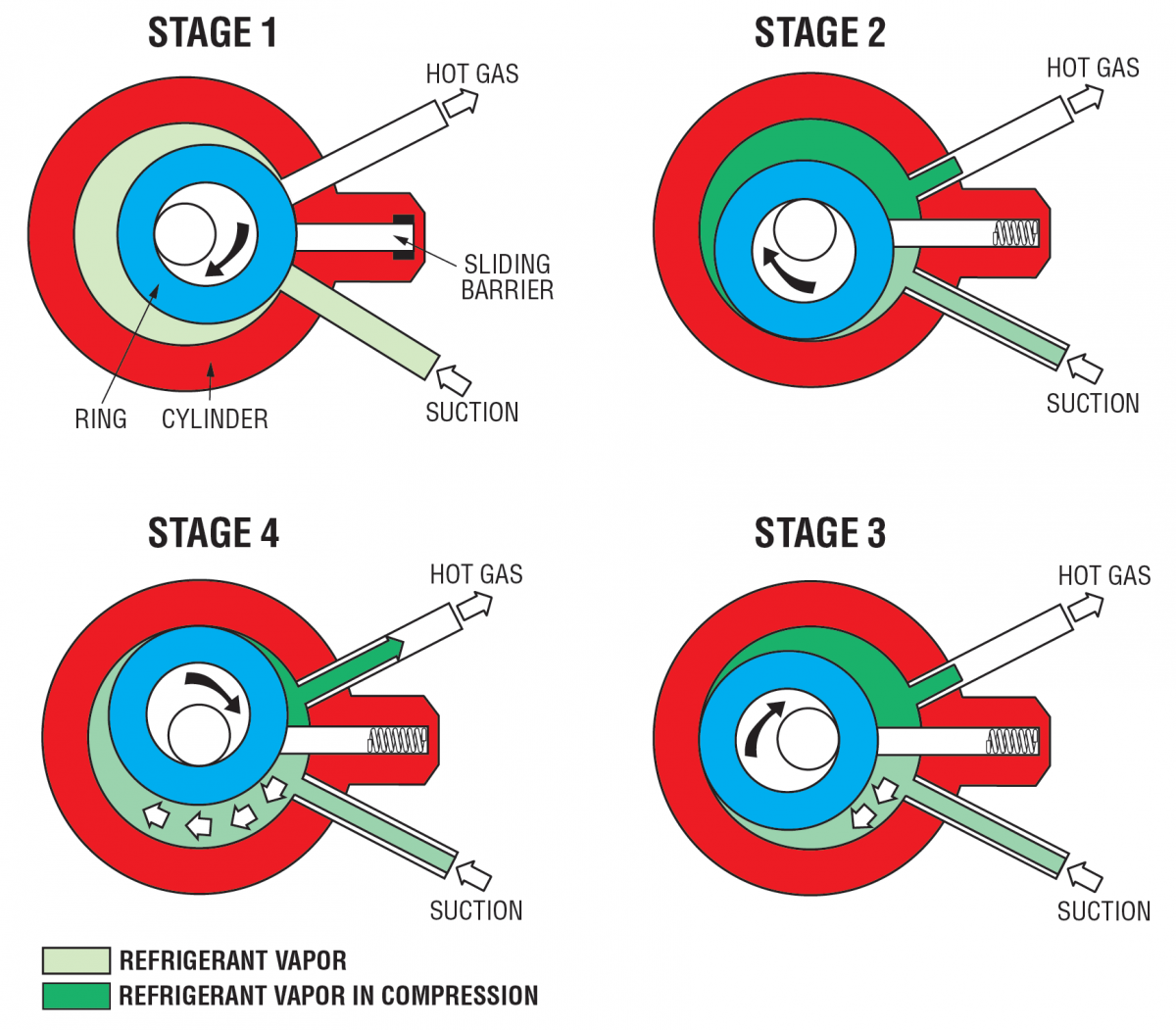

A scroll compressor operates in a similar manner to a rotary and is sometimes referred to as a rotary-scroll. The difference comes in the shape of the rotor and stator. The ring and cylinder are replaced with two scroll patterns. Both the rotor and stator are scroll patterns where the refrigerant becomes trapped between the two patterns and is progressively compressed as the rotor scroll is translated.

For a scroll compressor the first stage of compression is also the last stage of the previous cycle. The scroll is designed to intake and compress two different volumes of refrigerant at a time. During the next three stages the rotor scroll rotates driving the refrigerant into progressively smaller spaces until the volumes converge at the center of the scrolls fully compressed. Upon reaching the center the refrigerant is fully compressed and released into the hot gas line of the refrigerant cycle, no need for a valve to maintain the pressure prior to compression.

4-Way Reversing Valve

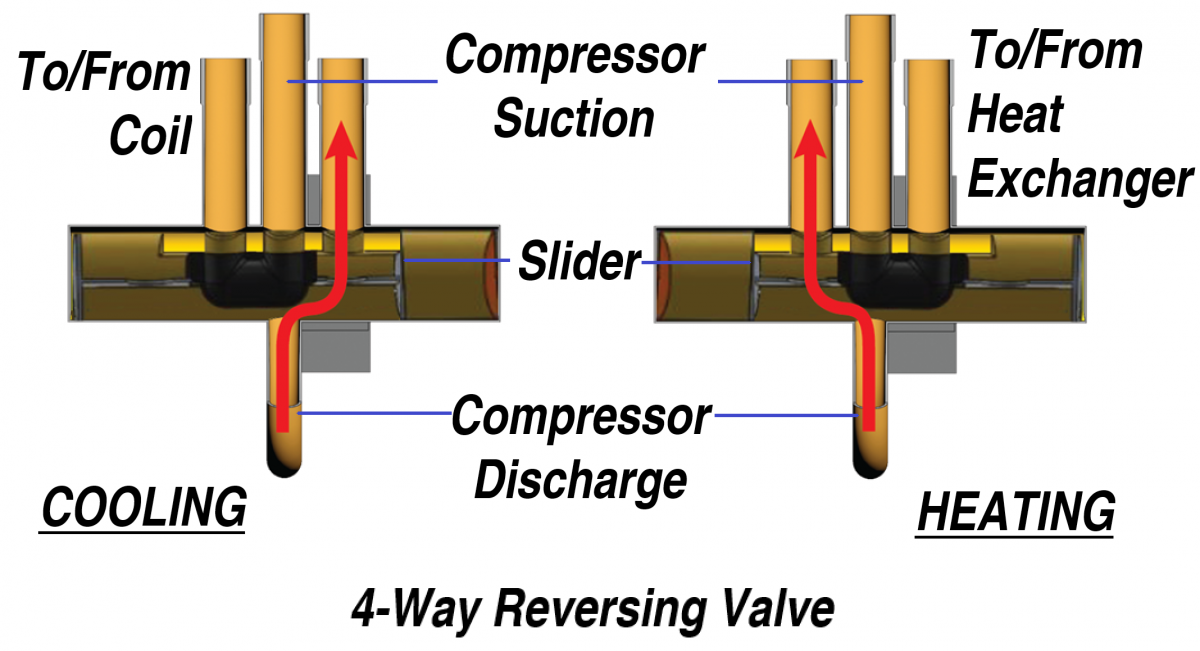

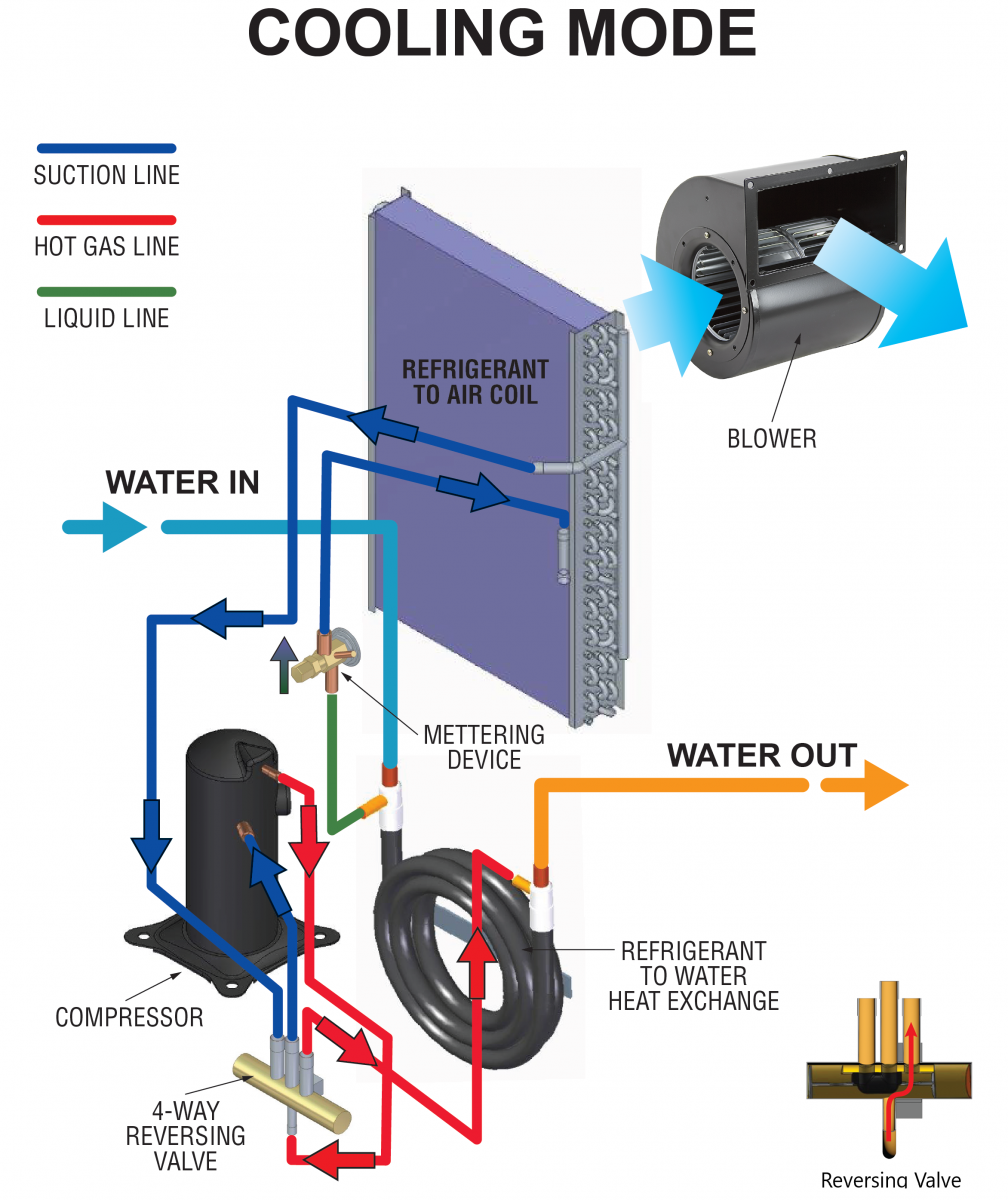

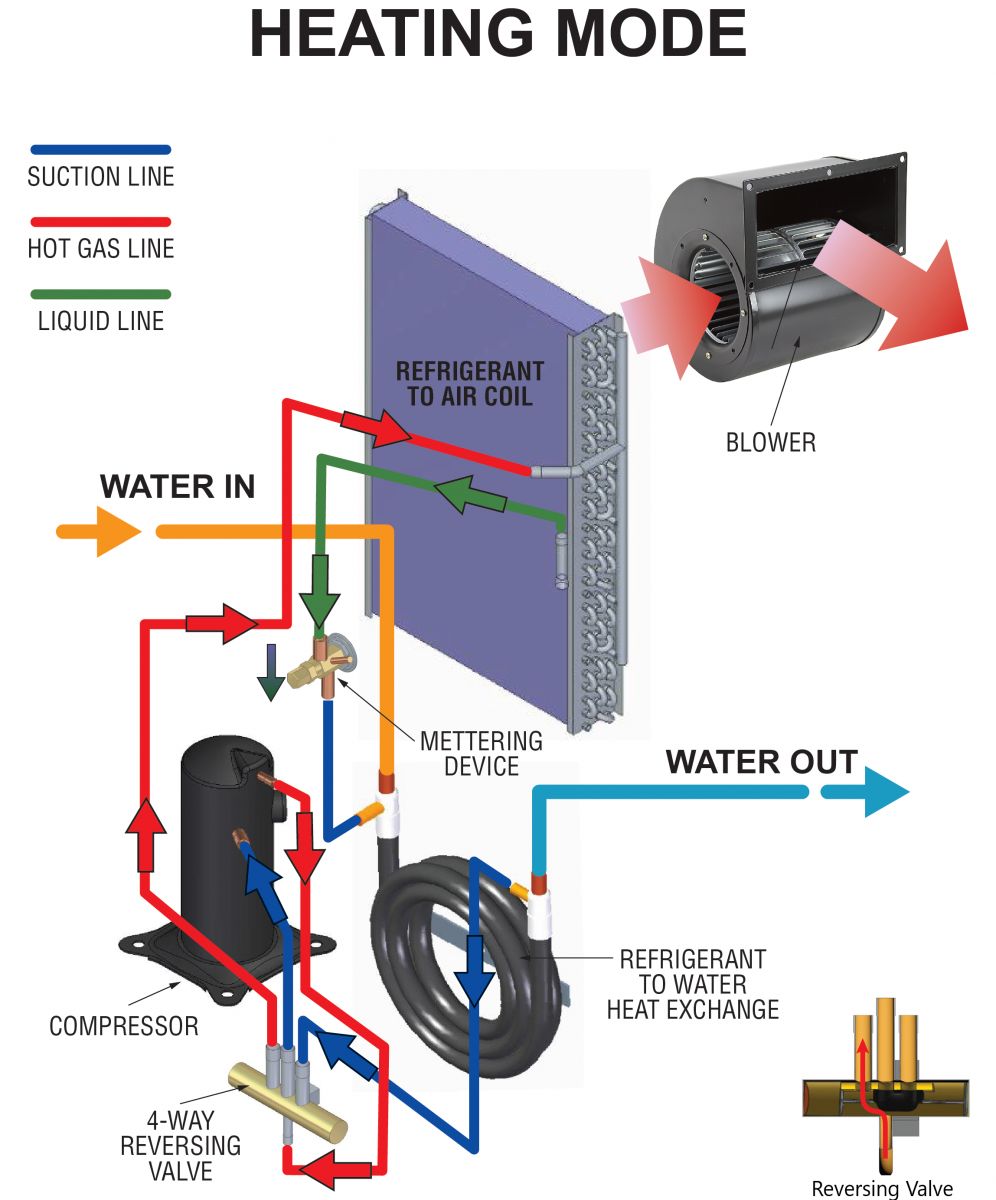

The 4-Way Reversing valve is the part of the system that makes a heat pump a heat pump, the component that separates heat pumps from air conditioners. The valve directs the flow off hot gas coming off the compressor based on if the space is calling for cooling or heating. When the hot gas comes off the compressor the valve will either direct the flow to the heat exchanger for cooling mode or to the coil for heating mode.

The valve body has a slider inside that shifts back and forth based on the call for cooling/heating. As shown on the graphics above, when the system calls for cooling the slider moves to the left so that the compressor discharge flows to the heat exchanger. When there is a call for heating, the slider moves to the right and directs the flow of the coil. The slider movement reverses the flow through the refrigerant cycle to either remove heat from the room or to add heat depending on the need.

Though the 4-way reversing valve has a huge impact on the operation of the heat pump, it doesn’t affect the refrigeration cycle and its operation will not be reflected on a refrigeration cycle plot.

Refrigerant-Water Heat Exchanger

In a cooling cycle, the refrigerant leaves the 4-way mixing valve and goes to the refrigerant-water heat exchanger. On the residential unit discussed above, the fan and coil on the outside unit are designed to reject heat to the outside air. The water source heat pump replaces the outdoor fan and coil with a heat exchanger. For this system to work the building provides a loop of water. This water loop includes a cooling tower and a boiler to maintain the water entering and leaving the unit for optimal performance.

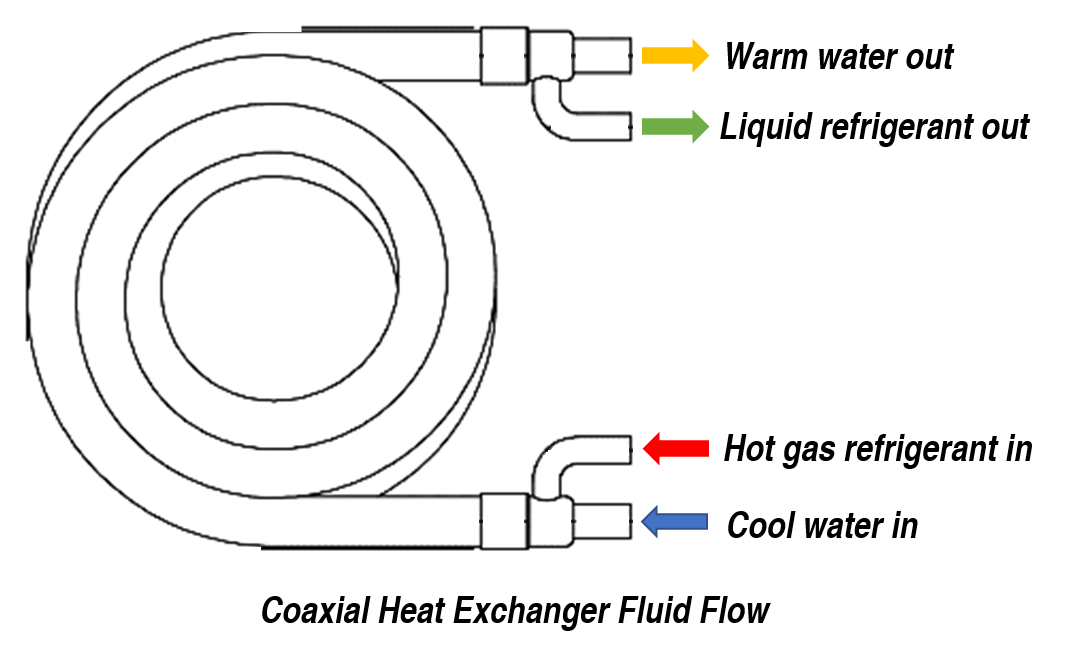

The heat exchanger is a coaxial design where the refrigerant runs through a tube on the ID of the heat exchanger and the building loop water runs between the refrigerant tube and an outer tube. During cooling, the lower temperature water draws the heat away from the compressed hot gas of the refrigerant. The water leaves the heat exchanger with a higher temperature and the refrigerant leaves as high-pressure low temperature liquid. This is shown as the second line on the PE chart below:

During heating, the refrigerant enters the heat exchanger after leaving the metering device as a low temperature low pressure mixture of gas and liquid. It draws heat from the building water loop and exits as warm temperature low pressure gas.

In order to fit the heat exchanger in the smallest amount of space, they have been coiled as shown above. The goal of this system is to reject/draw the most amount of heat in the shortest length of heat exchanger.

When there is a call for cooling/heating an automatic water valve located on the discharge of the heat exchanger will open, allowing the building water to travel through the heat exchanger.

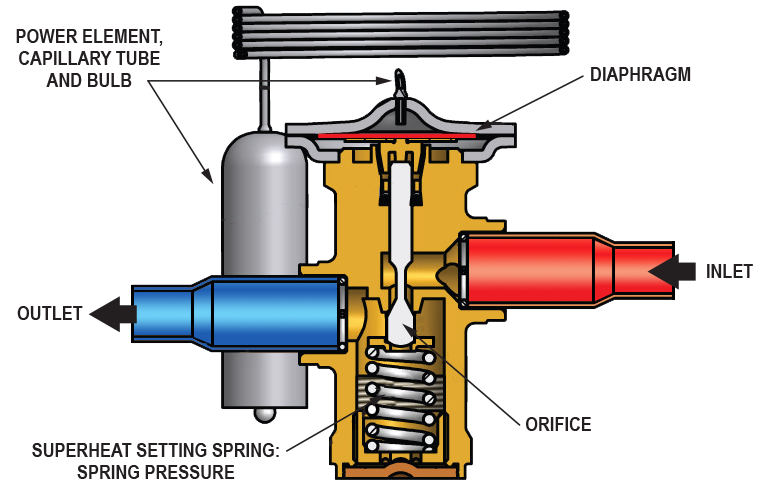

Thermal Expansion Device

Again, in the cooling cycle, the high-pressure low temperature refrigerant liquid leaves the heat exchanger and moves toward the thermal expansion device. This controls the flow of refrigerant into the coil. The thermal metering device separates the low-pressure part of the cycle from the high-pressure part coming from the compressor. When the refrigerant moves into the low-pressure area it “evaporates” and cools very rapidly. This is represented as the third line in the PE chart for R410a shown below, the refrigerant goes from a high-pressure medium temperature liquid to a low pressure low temperature mixture of liquid and gas.

Just separating the high pressure and low-pressure areas could easily be done by just a specifically sized orifice, but the thermal expansion device actively monitors the temperature of the refrigerant leaving the coil and adjusts to get the proper amount of cooling through the coil.

The Power Element Bulb Pressure sensor is installed against the refrigerant pipe leaving the coil so that it can sense the temperature. The tube from the bulb then routes to the top of the metering device. There is a fluid inside the bulb and the tube that either expands or contracts based on the temperature of the refrigerant leaving the coil. When the temperature of the refrigerant leaving the coil is too high, the fluid expands and acts against a diaphragm that then pushes the valve in the device open further allowing more refrigerant to enter the coil. If the coil is too cold, the fluid will contract closing the valve and releasing less refrigerant. In a world of smart homes and connected devices, it is a great piece of technology that relies on materials for control, not an electronic sensor and actuator.

When the cycle is reversed for heating, the thermal metering device has an integral check valve that allows the high-pressure low temperature refrigerant to pass in the opposite direction into the heat exchanger. In older versions, the check valve was located on a separate circuit that bypassed the thermal metering device.

Coil

Coil

The coil is designed to facilitate heat transfer from the air to the refrigerant. The goal of the coil design is to increase the surface area of the contact between the coil and the air. The coil is a series of tubes that are “coiled” back and forth. In between the tubes there are fins, mostly 14-15 fins/inch, that provide a large surface area for heat transfer. The size of the coil and the number of refrigerant circuits through the coil are designed to provide the right amount of cooling/heating to the space. During cooling, as the air passes through the coil it transfers the heat from the air to the refrigerant. On the PE chart, this completes the cycle turning the low temperature mixture of gas and liquid into low pressure medium temperature gas, ready to be compressed and to start the cycle over again.

Fan

The second largest user of electricity in the WSHP is the fan. The fan is designed in combination with the coil to provide the space with the proper amount of conditioning depending on the size of the unit. Most units today use a fan that has an Electro-Commutated Motor (ECM) for the highest efficiency. The Engineered Comfort Serenity WSHP line has a cooling and heating CFM and the fan adjusts based on the call for conditioning.

System

The refrigerant follows the paths below depending on cooling or heating:

- Cooling

- High Pressure Hot Gas leaves the compressor and enters the 4-way reversing valve

- The 4-way mixing valve directs the flow to the heat exchanger

- The now high-pressure lower temp liquid leaves the heat exchanger and enters the thermal expansion device

- Upon passing the expansion device and entering the evaporator coil, the refrigerant becomes low pressure very low temperature gas/liquid mixture

- The coil cools the air passing through it and refrigerant becomes low pressure medium temperature gas and moves back toward the compressor

- Heating

- High Pressure Hot Gas leaves the compressor and enters the 4-way reversing valve

- The 4-way reversing valve directs the flow to the coil

- The high-pressure hot gas warms the air passing over the coil and becomes a lower temperature high pressure liquid that is directed towards the thermal expansion device

- Through the expansion device the refrigerant becomes a low-pressure low temperature gas/liquid mixture and cycles towards the heat exchanger

- In the heat exchanger the low-pressure low temperature liquid becomes a low-pressure medium temperature gas and moves back toward the compressor

Water Source Heat Pump

For many reasons including low investment cost, efficiency, ease of maintenance, building aesthetics, and comfort the Water Source Heat Pump System is an excellent choice for a high-rise residential development. This is one article in a series of articles focused on water source heat pump systems. If we can do anything to help you with your system design, please reach out to us.