A large portion of the energy exerted by an HVAC system comes from conditioning the outside air required by the mechanical code, which typically reference the ASHRAE 62.1 standard. Increasingly, this is performed separately from the building HVAC system by a Dedicated Outside Air System (DOAS). When designing a DOAS system, one decision is how to distribute the air to the space. In my previous Ventilation Strategies article, I highlight a few methods for ventilation distribution. One method I didn't address in the article was Chilled Beams. Chilled Beams compete with the Chilled Water Fan Powered Terminal Unit as a tool for distributing the ventilation from a DOAS. Understanding how each of these tools work, their limitations, and the considerations for selection will help you decide on the best solution for your design.

Both systems utilize a DOAS to cool/dehumidify ventilation air that handles the latent load in the space. The chilled beams and chilled water fan powered terminal units have sensible cooling/heating coils to fulfill the remaining demand in the space.

How They Work

Chilled Beams

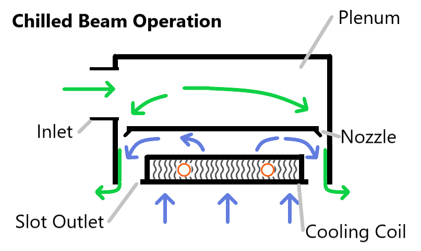

There are two chilled beam designs, active and passive. Active chilled beams have a primary air connection to a DOAS; passives do not. For purposes of this article, I'm focusing on active chilled beams. An active chilled beam has the following parts:

- Primary Air Inlet

- Plenum

- Nozzles

- Sensible Cooling Coil

- Slot outlet

The primary inlet is the connection from the DOAS to the chilled beam. The air flows from the inlet into the plenum. Once in the plenum, the air passes through the nozzle and flows into the slot outlet. The air accelerates as it leaves the nozzle, creating a low-pressure zone above the coil. The low-pressure induces room air up through the sensible cooling coil, into the low-pressure air stream, and through the slot outlet back into the room.

The chilled beam is located directly in the room it serves, conditions the room air through induction, and mixes it with the primary air. In chilled beam systems, there needs to be a chilled beam in every room that requires conditioning.

Chilled Water Fan Powered Terminal Units

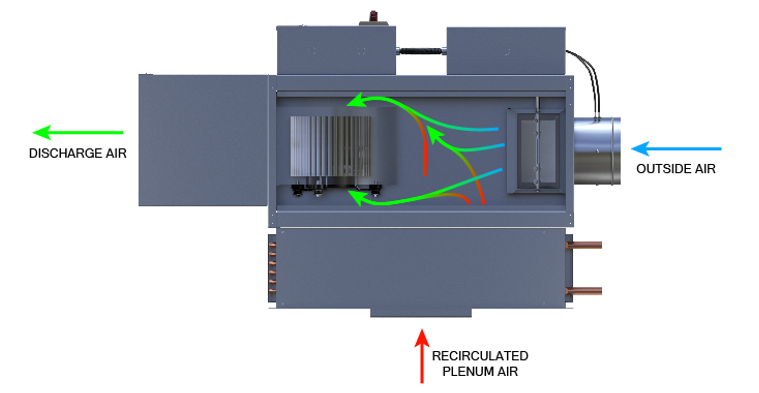

The chilled water fan-powered terminal unit is a series fan-powered terminal unit with a sensible cooling coil on the induction port. The terminal unit consists of the following:

- Primary Air Inlet

- Flow Sensor

- Damper

- Fan

- Sensible Cooling Coil

- Optional Heating Coil

The DOAS delivers ventilation air to the unit through the primary air inlet, which the flow sensor measures. This measurement ensures the damper does not allow the airflow to drop below the required minimum ventilation during occupied periods. The damper will control the ventilation if the system has implemented demand control ventilation. The fan delivers a mixture of primary and recirculated air from the unit to the space. When the cooling demand in the zone exceeds the amount provided by the primary air, as determined by the thermostat, the fan will induce more air through the sensible cooling coil and into the space.

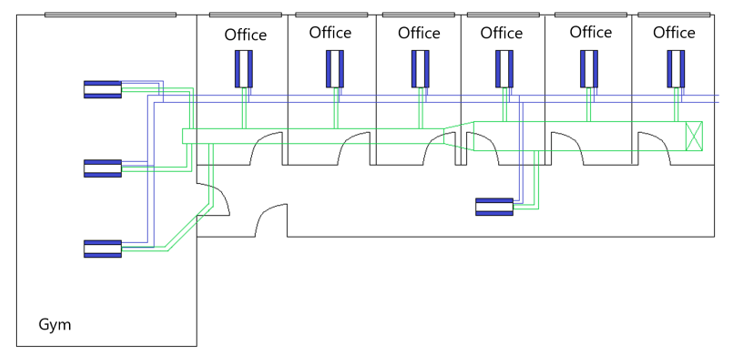

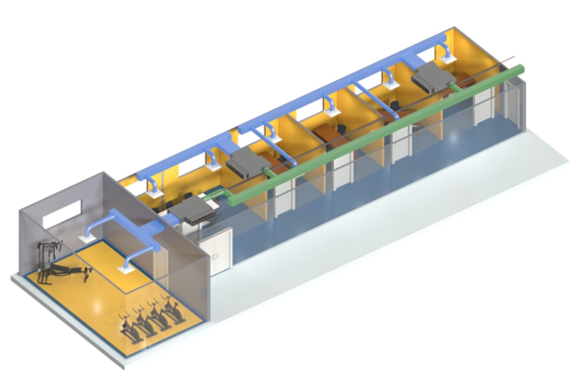

The terminal unit is typically located above the ceiling and can serve multiple spaces. The largest size that Nailor offers is the 33SZ-55, it can handle up to 2,000 CFM.

Benefits & Challenges

Chilled Water terminal units and chilled beams each have their features and benefits for delivering comfort.

Chilled Beams

Benefits

- No moving parts

- inherently higher reliability & low energy use

- Low profile

- work well in applications where ceiling height is a concern

- Beams required in every space

- controls to each room, rather than one control for multiple rooms

Challenges

- Require higher static pressure, 3/4" at the inlet, to operate

- Fan energy from the DOAS is a cube function of Static Pressure

- Coils are located directly above the space

- If space conditions change (someone opens a window) it could cause condensation to drip from the coils.

- Relies on primary air to induce room air through the coil

- Induction is a cube function of the static pressure at the inlet

- A slight reduction in primary airflow results in an outsized reduction in induction

- Renders chilled beams constant volume.

- Demand control ventilation becomes a challenge with chilled beams

- ADPI is more difficult to calculate, eliminating your ability to meet the requirements of ASHRAE 55

- chilled beams are linear, no ability to change the throw of the unit

- Each room requires a separate chilled beam system with its own piping connection

- Greatly increasing the first cost of the HVAC system

- Reduced flexibility increases the costs of renovation, especially in a transient office environment

Chilled Water Fan Powered Terminal Units

Benefits

- Multiple sizes enable one piece of equipment, and one water connection, to serve multiple spaces

- Less piping is required to serve the total area

- Much lower first cost

- The damper and flow sensor enable the control of ventilation air when paired with a VAV DOAS.

- employing demand control ventilation allows the ventilation energy use to be optimized based on occupancy

- The coil has a drip pan, so small changes in humidity won't affect the space

- There is little chance that water will drip into the room

- The fan controls the air to the space, no reliance on induction, so the fan can increase and decrease based on demand in the space.

- Building cooling loads are at 50% of design or less for 85% of the occupied times.

- Varying the supply is critical to occupant comfort

- The fan reduces the static pressure required at the inlet of the terminal unit, reducing the DOAS fan energy

- Air distribution is separate from the terminal unit, enabling accurate ADPI

- This also enables different air distribution designs, not just slots

- The design is more flexible to renovation or changes to the space layout

- Air distribution can be modified without affecting the terminal unit location and piping

Challenges

- The terminal unit is taller than a chilled beam so it does require additional ceiling height

- Noise does have to be considered due to the fan in the space

- Ductwork and air distribution equipment is required to serve the space

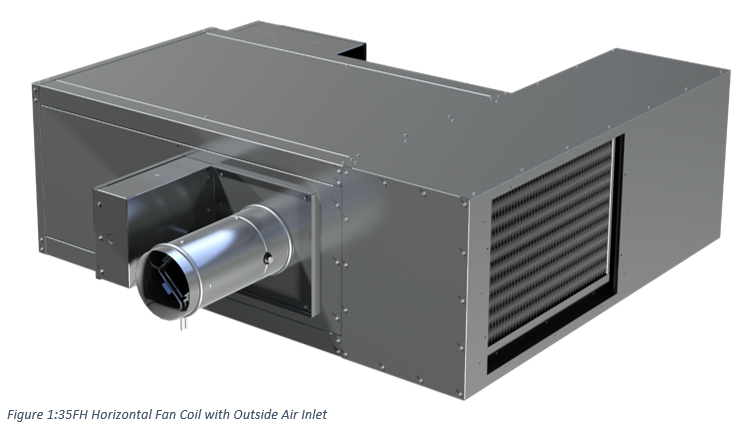

There are certainly applications for each of these equipment types, however, the chilled water fan-powered terminal unit outperforms on cost, flexibility, occupant comfort, and energy efficiency. Nailor offers a full line of Chilled Water Fan Powered Terminal units, model 33SZ, to satisfy the needs of your HVAC system. Additionally, the Nailor 35FH and 37FH fan coils can be used in the same manner as the 33SZ in applications where higher latent loads are a concern.